B and H was a motorcycle produced circa 1923.

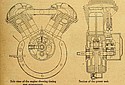

Primarily engine manufacturers, this company offered 247cc, 349cc and 498cc single cylinder engines, and 494cc, 698cc and 995cc V-twins. For a short time they also built a few complete motorcycles using the largest V-twin engine and bought-in parts.

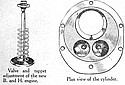

(L.) Valve and tappet adiustment of the new B. and H. engine. (R.) Plan view of the cylinder.

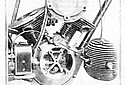

Detachable cylinder heads, which also give access to the valves, are one of the most outstanding features of this new 10 h.p. V twin engine.

(L.) Valve and tappet adiustment of the new B. and H. engine. (R.) Plan view of the cylinder.

A New Big Twin.

Distinctive Features of the B. and H. Engine.

THE unusually large and unconventionally shaped aluminium combustion heads with which the new 10 h.p. V twin B. and H. engine is equipped are its most noticeable peculiarity, for they do not accommodate valve caps, and, in consequence, the size of the cylinders is deceptive.

The bore and stroke are 80x99 mm. (996 c.c), and side-by-side valves of 1 5/8 in. diameter are used. Many new and distinctly interesting features are incorporated in the design, for which one of the designers of the Metric engine is responsible.

The timing gear has a separate cam for each inlet valve, while one only lifts the exhausts; the latter is positioned nearest the cam wheel pinion and has a lift of 13/32 in. The acceleration of the rocker is constant, whilst the device for raising the exhaust valves is exceptionally neat. Two pawls engaging a small shoulder on the exhaust valve rockers are lifted by a Bowden wire and hook. The former is carried in a tubular fixing in the centre of the timing case, and the latter lifts the ends of the pawls, and consequently the valves, via the tappets.

Adjustable Valve Stems.

The inlet valves are slightly offset in order that they may ride on the two cams respectively located on the outside of the timing wheel. An unusual procedure is the incorporation of the tappet adjustment with valve spring retaining washer. This design permits the use of plain rods for the tappets.

The complete valve spring and tappet are enclosed in a telescopic cylinder, whilst the head of., the valve is slightly concave.

Very careful consideration has been given to heat dispersion and the rapid expansion and exit of the gas.

The cylinder head is made with a number of cooling fins, which completely cover its surface, whilst air passes around both valve pockets located in the top of the cylinder.

The shape of the dome inside the head has been cleverly arranged to facilitate the passage of the gas both in and out of the inlet and exhaust valve pockets, respectively. Figures of interest are the diameter of the pockets. The inlet has a lin. diameter, whilst the exhaust is lin. wide. The actual pockets, however, immediately around the valve heads, are 1½ in. diameter.

Six bolts hold the head to the cylinder and are not continued to the crank case, thereby allowing for expansion.

The piston is fitted with two thin, deep rings. The skirt is, of course, grooved to assist the distribution of the oil.

An elaborate bearing layout is used - a most desirable feature - and it includes a double row of Hoffmann rollers for the big end, a roller bearing of the same make on the pulley side of the main shaft, and on the other side a Hoffmann ball bearing.

Gear-driven Magneto.

Two ball bearings are also used on the camshaft. It would be interesting here to mention that the magneto, which is bolted to a plate on the side of the crank case, is driven by a bevel and shaft from the cam wheel. In this position it is accessible and is protected by the large timing case.

Probably the most novel feature of this engine is the lubrication system. It will be more readily understood if the path of the oil be traced from its tank. An oil. lead from the usual type of dripfeed lubricator is connected to the front cylinder wall, where there is an annular groove. The piston, at the bottom of its stroke, descends sufficiently low to permit the oil entering the waist, from where it is spread around the cylinder by the piston grooves.

The surplus oil, however, drips into the crank case, and it is forced therefrom by pressure on the down strokes of the piston being carried via a ball non-return valve into a large annular chamber encircling the crank case.

Between these chambers, and in the faces of the crank case, is a groove connected by a small channel to the chamber.

Oil is forced into the groove, and thence via a small hole to the annular grooves around the base of each cylinder. It would appear, then, that the front cylinder is overfed, or the rear under-supplied, with oil. This, however, is equalised by the splash from the flywheels and the big end, the front cylinder having a loafile , whilst the rear is open. Two drain taps are fitted - one for emptying the annular chamber and the other for releasing the waste oil in the crank case. Other interesting notes would show that the valve spring tension is 45 lb., whilst the weight of the piston is 14 oz.

It is possible that experiments with aluminium alloys, will be made at a later date.

The manufacturers, the B. and H. Engineering Co., Ltd., Napier Works, Napier Road, Ponders End, Middlesex, entered one of these engines fitted in a Zenith frame, for the 600 mile race at Brooklands. This really constituted a trial from which the makers hope to gain some useful data.

A limited number of engines will be available shortly.

The Motor Cycle, July 7th, 1921.

Sources: Graces Guide, The Motor Cycle.

If you have further information or a query related to this page, please contact us