The milled and balanced crankshaft, and the cast aluminium piston, which has two unusually deep rings and two oil retaining grooves.

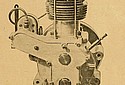

The special features of the "Buzmo " engine are its mechanical lubrication, outside flywheel, and overhead valves. The cylinder dimensions are 88.9 x 76.2 mm., giving 475 c.c.

Showing the combined timing and magneto gear cover removed.

SINGLE-CYLINDER motor cycles of entirely new design are few and far between, and to learn of a new 3 1/2 h.p. machine with an engine differing in many respects from general practice is always interesting. The machine to which we refer is the 3 1/2 h.p. "Buzmo," which at no distant date 4s to be placed on the market by the Portable Tool and Engineering Co., Ltd., of Enfield Highway, N.

Having a bore and stroke of 88.9 mm. and 76.2 mm. respectively, with 475 c.c. capacity, the cylinder is of cast iron, and fitted with a detachable head. The latter is hemispherical, and accommodates two tungsten steel valves, which are operated by rockers oscillating in bearings formed in two lugs on the cylinder head.

Two adjustable tappet rods transmit the lifting action from two rockers operated by a single cam wheel which is mounted above and meshes with the pinion on the engine shaft. Mounted on the cam wheel shaft is the chain sprocket which drives the C.A.V. magneto. The chain case is cast integral with the crank case. Below the main shaft pinion, and engaging with it on its under side, is another gear wheel of equal size, which is provided on the inner side with an eccentric on which ride two'steel plungers operating two oil pumps. The function of these two pumps is to force the oil, contained in the front end of the large petrol tank, through various channels to the engine.

The oil passes down a pipe, coiled to offer a greater cooling surface, to one of the delivery pumps located at the front end of the timing gear case. This pump consists of a steel plunger reciprocating in a brass cylinder, its forward end resting on the eccentric, whilst the rear end rests against a steel return spring. Two brass pipes, provided with unions, are cast with the pump cylinder, each equipped with a ball valve, the seatings for which, however, are located on opposite sides to each other in order to operate the flow and return of the oil forced through the pump.. The oil is forced by the pump to a channel in the crank case, which conducts it to the drilled crankshaft. Lubricating both the roller bearing on the pulley side and the plain bearing on the other side, the oil then passes to the big-end and' is forced by centrifugal force up a pipe mounted on the connecting rod to the floating gudgeon pin bush and the gudgeon pin, and thence to the cylinder walls. The oil collected in the sump of the crank case is drawn through a pipe to the second pump, and is forced, through a sight-feed lubricator, back to the tank, providing a continuous flow of oil.

An Aluminium Alloy Piston.

An aluminium alloy piston has two oast iron rings of unusual depth, and is provided with two annular slots around which a number of small holes are drilled. The edges of these slots, nearest to the centre of the piston, are cut at right angles, whilst the outer edges are bevelled; consequently, on the up and down strokes of the piston, oil is collected by these bevelled edges and contained in the slots, thereby distributing oil around the cylinder walls.

Fitted with the heavy pattern Druid spring forks, the frame departs somewhat from the conventional, the engine-supporting tubes being of the twin type. The wheels have knock-out spindles, and are, therefore, quickly detachable, while the rear wheel is equipped with an internal-expanding brake in the hub and also a shoe brake acting in the belt rim; both are heel-operated and Ferodo-lined.

Both front and rear mudguards are of ample width, and are fitted with side shields.

Negotiations for extensive premises are being made, and it is confidently anticipated that the machine will be produced in quantities early next year at a price between fifty and sixty guineas. A limited number, however, may be available before the end of this year. The "Buzmo" is designed as a simple solo single, and, as such, there should be a brisk demand for it on the part of those who desire a sporting machine for solo use.

The Motor Cycle August 28th, 1919. p223

The Buzmo was designed and developed by Bert le Vack and John Wallace.

If you have a query about about this page, or have some information to add, please contact us