When J.J.Coro, webmaster of the site motosdfr.free.fr devoted to DFR and Dresch, sent me, among many others, the copy of the article evoking the Cargnelutti engine, I did not immediately realized what it was all about.

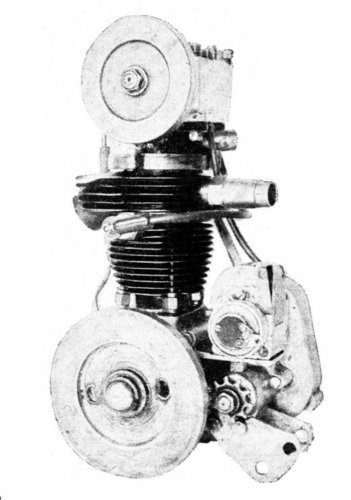

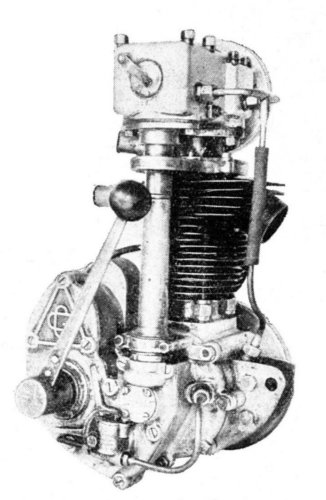

It was only after re-reading the article carefully that the "thing" caught my attention. One cannot say, however, that the engine, seen from the left as from the right - opposite - has, in itself, an innocuous and traditional aspect! Here is, below, the complete text of the article in question, dated 1930, supposed to let us know how it works:

"The combination of cycles is obtained by means of two driving elements working according to two different cycles.

The explosion chamber is unique. There are two cylinders in tandem and two pistons of different diameter.

The piston with the largest diameter moves at twice the speed of the piston with the smallest bore.

The first works according to the four-stroke cycle, the second according to the two-stroke cycle.

The illustrations make it possible to realize the arrangement of the organs.

The operation is as follows:

Suction occurs when the piston of the four-stroke element moves from top dead center.

During this time, the two-stroke element piston completes half of its stroke from bottom dead center.

As a result of the difference in the diameter of the two pistons, a depression is produced which is filled by the gases which arrive through the opening uncovered by the piston and the rotary distributor.

When the reverse movement occurs for the piston of the four-stroke element we have the compression stroke in which the piston of the two-stroke element completes its stroke and has blocked the intake port.

During working time, the two pistons move towards their lower dead center.

By the time the four-stroke element piston is at the low point, the two-stroke element piston is only halfway through its stroke and unmasks the exhaust port.

Raising the piston of the four-stroke element assists in the expulsion of gases.

Then arrives in the cylinder a flush of fresh air blown back by the casing of the two-stroke element.

What are the advantages of this type of engine? It is first of all the extension of the intake and exhaust phases.

Desmodromic control ensures the possibility of running at very high speeds. The thermal efficiency is excellent, the gases expand in a larger space than that of a classic four-stroke and for a longer time and in addition a good part of the energy, consumed in the intake stroke and in the exhaust stroke. exhaust is recovered.

Of course, the applications of this engine are not limited to motorcycles, but extend to all branches using internal combustion engines and in particular aviation."

To this text and these overall photos were attached other detailed photos, more precise, allowing to see certain internal elements of the engine:

Set of lower and upper cylinders Upper crankcase, with its piston. Lower crankcase, with its piston, the gearbox and its control lever

If it was not necessary to turn these photos in all directions to realize that we are in the presence of something unusual, the text did not seem to me, from the outset, of a clarity obvious. We understand, of course, that we used a two-stroke engine, instead of a conventional cylinder head, to manage the intake and exhaust of a four-stroke engine. However, many "grey spots" remained, particularly with regard to a mysterious rotary distributor. So, I reread the text sentence by sentence and I took a paper and a pencil to break down the different phases of engine operation. I then transcribed these drawings. I couldn't avoid sharing it with you:

There are a lot of details missing from these diagrams. More specifically the vertical shaft allowing the 4 stroke to drive the 2 stroke. It is, in fact, the same shaft as that which, on a conventional engine, would drive an overhead camshaft. The latter being, here, replaced by the 2-stroke linkage.

Above all, it lacks this rotary distributor which is mentioned in the text and whose habits lead us to look for it arranged parallel to the crankshaft of the two-stroke engine.

In fact, it does not manage the intake in the lower crankcase, but the transfer of gases between said crankcase and the "combustion chamber" common to two-stroke and four-stroke engines (see doc. on the left). Its periphery is fitted with teeth, this disc being driven by a gear located on the vertical axis connecting the connecting rods of the two motors (see document on the right).

|

Accompanying this text and these overall photos were other, more precise, detailed photos showing certain internal elements of the engine:

|

||||||||

|

While it wasn't necessary to examine these photos from every angle to realize that we were looking at something unusual, the text didn't strike me as immediately clear. We understand, of course, that a two-stroke engine was used instead of a conventional cylinder head to manage the intake and exhaust of a four-stroke engine. However, many questions remained, particularly concerning a mysterious rotary distributor. So, I reread the text sentence by sentence and took out a pen and paper to break down the different phases of the engine's operation. I then transcribed these drawings. I simply had to share them with you:

These diagrams are missing quite a few details. In particular, the vertical shaft that drives the four-stroke engine and the two-stroke engine is missing. This is, in fact, the same shaft that would drive an overhead camshaft in a conventional engine. Here, the overhead camshaft is replaced by the two-stroke engine's connecting rod. Most importantly, the rotary distributor mentioned in the text is missing, and we tend to expect it to be positioned parallel to the two-stroke engine's connecting rod. In reality, it doesn't control the intake into the crankcase, but rather the transfer of gases between the crankcase and the combustion chamber common to both the two-stroke and four-stroke engines (see left-hand diagram). Its periphery has teeth, and this disc is driven by a gear located on the vertical axis connecting the connecting rods of the two engines (see right-hand diagram).

To try and learn more about it, I shared my "discovery" with Henk Cloosterman ( members1.chello.nl/~wgj.jansen/ ), a specialist in desmodromic valve actuation engines who was conducting his own investigations. One of his contacts informed us that a very similar engine, based on the same principle, had been developed in Australia by "Beare Technology" ( http://www.sixstroke.com/pageone.htm ), apparently without them ever having been aware of the existence of the Cargnelutti engine. This omission has since been rectified. |

Source: Moto-Histo.com

See also Beare Sixstroke