COMPARED with the leviathans of Small Heath, Plumstead and Meriden in their heyday, it isn't much; a tiny factory and a jumble of out-buildings, Portakabin[1] and steel stock tucked behind a quiet Kent village. But small is, as they say, beautiful, this tranquil spot is the only place in England you can go to and expect to wheel away a machine to beat all comers. The firm is called Godden Engineering, and it makes possibly the best long-track and speedway bikes in the world.

Don Godden, founder and proprietor of the business, has paralleled the development of the sliding game since he took up grass-track in 1953. In those day the sport was, as he puts it with characteristic candour, "still in the Dark Ages'. Most of the machines were converted scramblers with the odd speedway iron thrown in, and there was nothing remotely purpose-built. Don himself began on a BSA Bantam, which also served for trials, scrambles, getting to work and the odd run-in with the local bobby. Those were the days!

In the late fifties, that other doyen of the sport, Alf Hagon, started chassis-building, and his frames were soon the gear to have. Don was himself using the ubiquitous JAP engine in one of Alf's frames and enjoyed a long and fruitful relationship with the Hagon concern, which culminated in him winning the world long-track title in 1969. However, the same engineering background and curiosity which made him such an able development rider also brought with it a wish to innovate and improve. Although he built his own, quite successful frame in the early sixties, this interest had for many years to play second fiddle to his racing commitments. In 1968 Don bought out a two-man agricultural engineering firm in Aylesford. (He had in fact served an engineering apprenticeship with a company making agricultural spraying equipment, there he'd gained production experience in a firm similar in size to Godden Engineering now. Alongside the established production facilities and customers, the motorcycle side of the business was gradually developed.

Don was already tuning JAP engines, which he seemed able to breathe extra life into, and progressively developed the chassis into quantity production by 1970. Although the factory was gutted by fire in 1973 (the only surviving relic being a charred ACU Star - See above Photo) this side of the business has continued to prosper. But, in talking with Don, it's clear that engines are what really arouse his passions. For years JAP engines (of basically 1930s design) had dominated the sport, but with familiar British board-room complacency had almost totally succumbed to the two-valve Jawa by the early seventies. During this period the power characteristics required of speedway motors had changed radically, for surprising reasons. Firstly, wheel size, were regulated from 22 to 19 inches and secondly, speedway tracks changed hand from speedway to greyhound promoters! The tracks themselves became smaller, usually being resided inside the dog tracks. Track owners naturally objected to shoveling tons of shale off the dog track after every speedway meeting, so they merely did away with the stuff. Consequently the tracks hardened, rubber compounds became more critical and riders could lay down more top-end power (as long and grass-track competitors always had).

Jawa responded to this, JAP didn't, and became even less committed when sold out to Norton Villiers who were indifferent to speedway. The JAP was briefly exhumed by Alec Jackson and George Greenwood but, with insufficient I resources, the project foundered. Elsewhere a derivative of the Matchless GBOCS began encouraging development with Don's help, but by then AMC were already at death's door. A B50-based engine showed similar potential at the hands of Eric Boocock, but met a similar fate when BSA went to the wall. All this left Don with a flourishing chassis business and the increasing prospect of nothing to power the frames with, as JAP engines and spares ran out. Jawa declined to supply separate engines.

By chance Don already had a relationship with Weslake who'd flow-tested his tuned JAP heads. Equally it was becoming clear that the top-end power available from four-valve motors was increasingly suited to speedway, Weslake knew a bit about such heads. In fact, Neil Street had built almost single-handed a four valve engine in the early seventies which had frightened a lot of big reputations. Out of this, and particularly the enthusiasm of Weslake's Ron Valentine, came the Weslake four-valve speedway engine. The prototype debuted at Lydden in September '74. It didn't win (it was sidelined by an electrical fault) but showed tremendous power and much impressed the likes of Peter Collins and Ivan Mauger. For once the press raved positively, which more than anything else gave Weslake the courage to proceed. Thus Don had his engine (he and Dave Nourish being sole suppliers) and the firm prospered as the Weslake all but took over the sport.

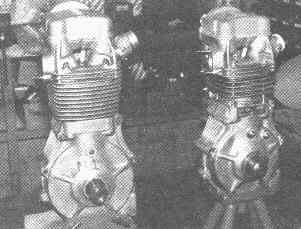

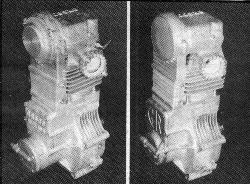

Pictured below are two versions of the GR500. On the Left is the original Mk1 prototype engine that was born in December 1978. Alongside it on the Right is the later Mk4 version (Eng. No. 620) just before its dispatch to former British Champion, Steve Bastable.

Specifications

However, in early '78 Weslake set up their own dealer network, removing Don's exclusivity, at the same time jacking-up prices considerably. Under these circumstances most of us would seek a quiet corner. Don set to and built his own engine. The project swallowed £120,000, half borrowed and half raised from the existing company. But, far from regarding himself as a gambler, Don was confident of a market for a British-built engine which he never doubted would be competitive.

The design parameters were relatively clear. FIM regulations required an under-500, single cylinder, single-plug engine (with, since '82, a 34mm carb limit). Don aimed for a slot between the dohc four-valve Jawa and the pushrod Weslake, it would have to be simpler and more reliable than the fastidious Jawa, and faster than the Weslake. The engine was first shown at a London show in January '79 and went into volume production for the following season. Production has risen from 50 units in that first year to 177 in '83 and 158 in the first seven months of '84. The engines retail at £882 each, a complete speedway bike costs Ł1800 and a grass-tracker is yours for £2,500.

Not that this meant instant profits. As if 21 per cent interest were not enough, at the time the Godden engine went into production Jawa were flooding the market with 1,000 units a year, which Don estimates to be the world-wide demand. Throw in Weslake the Italian GM and the knowledge that the Eastern bloc can undercut anybody on price if they wish, and it's no surprise that Godden only returned to profitability in '83. Lately the market has assumed some sense, partly through the demise of Weslake and Godden's target is 33 per cent of that market.

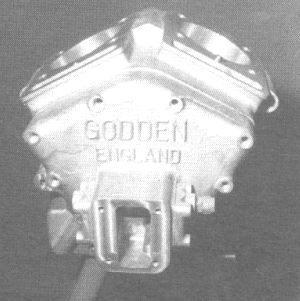

Pictured, the latest 1986 model, whilst the other is it's predecessor, the ... the Mk5.

The engine is, like all good designs, essentially simple. It weighs a mere 641b (29kg) and contains but two shafts, crank and cam. The latter is overhead, chain-driven at half time and carrying the ignition system of the customer's choice. Valves, with a narrow 20 degree included angle, are actuated by forked rockers with a screw adjuster per valve. Three cam profiles are available - long overlap for grass tracks, short for sidecar use and medium for speedway. Compression ratio is 12:1 for speedway, and up to 14:1 for grass, all naturally on methanol. The full-squish pistons are forged, of aluminium alloy to aerospace spec, and wear two compression rings. The total-loss lubrication requires no oil scraper ring. The oil pump itself is manufactured by Godden and driven directly from the crank, a carefully metered amount of oil is fed separately to specific bearings, almost in the manner of Suzuki Posilube. Conrods are again of aero-spec aluminium alloy with a phosphor-bronze small-end and a roller big-end running on a press-fit insert. All machining is carried out in-house, much of it on computer-guided machinery.

Flywheels are of very tough EN4OB steel and nitrided, Don is particularly proud of the reputation for reliability of these enormous lumps. Engine castings are of LM2S, an aluminium alloy with a high proportion of magnesium, for strength rather than lightness, they're heat-treated and all critical components are crack-tested, either Ardroxed or more elaborately as required. Dyno testing has shown Amal carbs to give the most power - about a giddy 64bhp at the crank. Flow-rate is all on speedway engines as methanol is delivered practically by the bucketful, so fine-metering accuracy is redundant. Incidentally Gardner carbs give a huge horsepower gain, but the flat slide only closes half a lap after the throttle, by which time the rider is in the catch fencing - evidently the fat engine pulses make the slide ratchet shut. Maximum safe revs are a heady 12,000, although with a 34mm carb the mill runs out of breath at 9,000. Some indication of the single's success is the fact that it comprised half the field in the 1984 World Speedway Final and ten of the eighteen runners in the World Long Track Final.

The Magnum shown here is the actual Godden GR500 machine that was ridden in the last World Final by Hans Neilsen before the advent of the new Grand Prix format. (Please see Footnote.)

One problem bemoaned by many manufacturers on this scale is the unreliability of suppliers. Although Godden carry out as much work as possible on site, they are inevitably dependent on contractors for anything from castings to nuts and bolts. And yet Don is dismissive of the problem, attributing it to sloppy production schedules and liaison, to not keeping suppliers appraised of anticipated demand. He points out, tellingly, that many suppliers are even smaller and lower capitalised than Godden Engineering and require absolutely this consideration.

Having established themselves with the single and identified the limits of their market, Godden were looking to diversify. The obvious and well trodden route was to mate two top-ends to a common crank, and thus a l,000cc V-twin is now undergoing development for sidecar competition. Despite his obvious passion for his products and their British pedigree, Don is a realist and a businessman, yet the gleeful way he describes the Vee as sounding `like tearing calico' suggests he'd happily go bust just as long as he had the noise on tape.

Footnote:

Søren Kjær recently mailed me to mention that in fact the Hans Neilsen machine depicted above is not truly a GR500 as I'd reported.

The GODDEN MAX was a further developement of the Mark 5 engine. It was the last Godden with total loss lubrication. Due to environmental reasons it had a waste oil collector mounted behind the crankcase that needed emptying from time to time. The Goddens up to and including the MAX had the ignition timing mounted at the right end of the camshaft behind the cover, where you can see the lead going in. Earlier models had breaker contacts, same as on a Morris 1000. ( a pain in the ..., if you ask me ) Later an electronic sensor gave the impulses. The Magnum engine, as you can see it on the picture you've got from Thomas Irming, has a Motoplat ignition system mounted behind the cover with the blue letters GR. (excellent system, unfortunately Motoplat went down the drain) You can also see the big housing for the oil sump on the right side, and the hose for recirculating the oil is also visible.

Notes:

1. Portakabin builds pre-made steel buildings used to construct anything from builders sheds to two-story houses.

Minor edits Sept 2017, Nov 2021.