FEATURES:

DESCRIPTION OF MOTOR CYCLE.

The World Champion WESLAKE pushrod and S.O.H.C. engines has been designed for speedway and long track racing.

Its frame is fabricated from special steel tubes, the centre and rear parts of which are bolted together. The telescopic front fork has a travel up and down of 50mm. The rear wheel is not suspended. The steering column rotates in bushes. The frame is painted in stove enamel (aluminium silver). The engines are aircooled, and are of a S.O.H.C. and pushrod type vertical single-cylinder unit with a swept volume of 500cc. The engines are made of a special alloy. Valve seats are shrunk into the cylinder head. The S.O.H.C. engine is chain driven. The valve springs, - two for each valve - are helical. The big-end and small-end bearings are of the plain roller type with aluminium-steel cages. The piston is a forging of light alloy with two piston rings.

The total loss-oil lubrication system of the engines incorporates dual

pump delivering pressure oil to the crank assembly and the cylinder head.

The leakage path oil lubricates the valves and the timing gear. The volume

of oil delivered to the head can be checked through a side glass and adjusted

by means of one screw.

The ratio of the primary transmission, which is chain driven to the

C/shaft, can be changed by altering the sprocket on the engine. The multiplate

clutch is dry. The rear transmission is by 5/8" X 1/4" chain and the ratio

can be changed by altering the rear wheel sprocket.

MAKING THE MACHINE READY FOR RACING:

Before starting the new engine or an engine which has been out of operation

for a length of time. Remove the cylinder head cover and pour some l00cc

of oil on the cam for pushrod engines on the rocker arms. This oil will

lubricate the timing gear and keep it lubricated until the pump starts

delivering oil.

Should the oil pump fail to deliver oil almost straight away, then

the union on the oil input to the pump should be slackened of in order that

the pump is primed and free of air. When oil is started to be pumped then

the union should be tightened.

The engine can be started either by pushing the machine or by rotating

forcibly the rear wheel with the machine resting on a stand.

The engine must always be warmed up using low rpm's. A new machine

should always have one or two good warm up before racing. Excessive rpm's

at light loads can cause damage to the engine.

CARBURETTOR ADJUSTMENT:

The carburettor is adjusted to methanol. It has to be readjusted when racing in other climatic conditions. With engines running on alcohol fuels, the high evaporation temperature is used for internal cooling of the engines, especially the piston. Adjusting the carburettor to a lean mixture is risky since it is likely to result in burning of the piston when running at full throttle, even for a short time. Therefore adjust the carburettor proceeding from the large jet to the smaller jet and never the reverse.

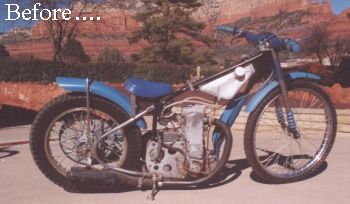

What can you say? .......

Truly a First Class job Rick, you

should feel proud of this excellent restoration. To see Rick's work in

progression, take a look at the "Rick's Restoration" Page.

**NOTE: Rick was not altogether

sure of his particular model and writes:

"I decided to call Antig and speak

to a Mr. Perry, Owner/Director of Antig. He did tell me that the SOHC that

I have is the earlier one with the single bolt holding down the valve cover.

The production on that one he said was around 200 or so. The later one

that has 6 hold down bolts they made more of. He also told me that if I

needed spares to give him a call as he had most of anything I might need."

Many thanks Rick.