Left side view showing one of the brake pedals. It should be noted that this is on the same fulcrum as the pedal on the opposite side, but extends rearwards instead of forwards as is the case with the right side brake. Thus the rider has a brakepedal convenient to his foot in whatever position on the foot-plates his feet may be placed.

Right side view of the Cedos two-stroke, illustrating the double brakes on the belt rim, and one of the conveniently placed pedals.

Both brakes on the Cedos operate on the belt rim, and have a common take-off spring.

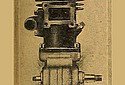

(Top) Piston, connecting-rod, and crank-shaft assembly. Note the method of fixing the gudgeon pin.

(Bottom) The built-up crankshaft, showing method of fixing, and the roller big end.

Front view of the engine, showing the exhaust outlet with machined ports.

Of the parallel link type, the Cedos spring fork embodies a single coil spring centrally disposed.

Contained in a circular case, the Cedos gear box is of the simple dog clutch type. The main driving pinion is supported on a ball bearing carried in the spigoted cover plate.

The Cedos piston, which is machined all over. The inset shows an enlarged view of the gudgeon-pin fixing.

THERE are two ways of constructing a reasonably priced motor cycle; one method is to skimp finish and fittings, and the other is to lay out a design in the first instance for mass production, every part being designed so that it is immediately interchangeable and drops into its place without any unnecessary fitting. The former method is, unfortunately, so common that it is a real pleasure to examine a machine falling into the latter class.

Messrs. Hanwell and Sons, Components, Ltd., Northampton, are about to market one of the most carefully thought out, lightweights that we have yet been privileged to examine. In spite of the fact that at the present moment only one complete machine has been built, there are absolutely no loose clips or fittings of any description. Every detail is so designed that it is brazed or welded directly to the particular part of the frame to which it belongs, and, in consequence, there should be a minimum of rattles.

Three-port Ball Bearing Engine.

The engine of this machine is a 2 1/4 h.p. two-stroke, having a bore and stroke of 62 X 70 mm. It is of the usual three-port type, and is designed and made entirely on the company's premises. There are no very unusual features about the power unit, with the exception of the fact that all parts are beautifully made, and that the crankshaft, which runs on ball bearings with plain bearing compression retainers, is built up of two parts, in a rather ingenious manner. The driving side of the crankshaft is constructed in one piece with the crank pin which registers in a hole in the crank web on the magneto drive side, the two parts being held together by a bolt passing through the middle of the pin. Both the inside of the pin and the outer diameter of the bolt are carefully ground to size so as to ensure an accurate and tight joint.

A roller bearing big end having Hoffmann rollers is employed, and the connecting rod, which is a particularly fine piece of work, is a very light steel stamping carefully case-hardened in the race and on the sides abutting the inside of the crank webs.

Piston Machined All Over.

A light piston carrying two rings at the upper end is fitted, and has a head formed in such a manner that it can be machined over the entire surface, inclusive of the transfer side of the baffle. The hollow gudgeon pin is ground very slightly taper, and is locked in position by a spring clip passing through holes in the pin and locking into corresponding slots in the piston.

All ports have been carefully designed, and are divided into two parts, so as to prevent the piston rings from catching.

Lubrication is effected by a sight feed drip, the oil being conducted to a point in the cylinder wall opposite the end of the gudgeon pin. Thence the lubricant is collected in a groove round the baffle plate in the top of the crank case, and is led by drilled ducts to the compression retaining bearing on either side of the , crankshaft. Each of these bearings is provided with an internal and helical groove cut in such a manner that the oil is drawn inwards towards the centre of the crank case.

Features of interest are common, one of the simplest being that studs are not employed for holding down the cylinder, but bolts are passed right through, lugs at the base of the cylinder and at the top of the crank case casting. This obviates any possibility of studs becoming loose in the aluminium.

A comparatively small diameter fly-wheel is fitted, and the transmission to the gear box is by 1/2 in. X 1/4 in. chain.

The carburetter employed is very ingenious, but we are unable to describe it fully at the present moment, owing to the patent being still incomplete. The strong point of this carburetter is that it embodies a variable choke, and enables the, engine to run extremely slowly and two-stroke regularly.

A Sane Gear-box Mounting.

A very simple two-speed gear box of the constant mesh type is enclosed in a circular box, and this box in its turn is fitted into a circular lug, which forms the bottom bracket of the frame. Both box and lug are carefully machined to fit, and the box is positioned by a large split clip. To adjust the tension of the driving chain, it is, therefore,, only necessary to slack off the single bolt holding this clip, and rotate the gear box through a few degrees by means of a tommy-bar. This method of fixing prevents any possibility of the chain wheels getting out of line, and as the dogs are operated by a Bowden control, a movement of the gear box does not entail any adjustment to the gear control. This control is operated by a thumb lever directly below the spark control, and in a similar manner to the throttle lever.

The final drive is by a 3/4 in. belt running over a 6in. front and 18in. rear pulleys. In this connection it must be mentioned that the belt is so guarded that slip should be unknown.

The valances of the rear mudguard come well down to the belt rim, and a special underscreen is so arranged that it forms the lower part of the rear mudguard, spreading out on either side to the aluminium footboards, and terminating at the front end in a shield, which effectually protects the lower part of the rider's legs from mud thrown up by the front wheel. We have seldom seen more complete arrangements made for the manufacture of frame and fittings. Every frame is constructed on special jigs, so that it is to all intents and purposes impossible for any variation to occur. Special forks are constructed by the manufacturers , which are very neat and light, although their strength has been well tested and proved. They are attached to the head by the usual parallel links, and their action is limited by a compression spring situated between the blades of the fork. The lower end of this spring is carried on a bridge piece integral with the fork, and the upper end by a swivelling housing connected to a lug at the bottom of the steering column. The top links are somewhat shorter than those at the bottom, so as to provide the double motion necessary for good front springing. Incidentally, it should be mentioned that the steering head is unusually long, and the ball races large.

In spite of the sloping top tube, which gives the machine a neat and practical appearance, the tank holds almost two gallons of petrol. The colouring of the motor cycle is in a shade of, purple, the frame being of a slightly deeper tone than the tank.

The manufacturers do not believe in front wheel brakes, and, consequently, we find two brakes acting on the belt rim - one on the inside of the V is operated by the right toe, and one on the outside of the V by the left heel. The brake rods are neatly arranged and lie parallel to each other, and a single coil spring serves to return both shoes to their "out of action" position.

24in. X 2 1/4in. tyres are used, and every part of the machine, with the exception of rubber and leather goods and ignition appliances, is manufactured in the firm's own works.

A detail which shows the practical mind of the designer is instanced by a small portion of the magneto chain case, which is quickly detachable, so as to provide easy access to the rear cylinder nut, which would otherwise be somewhat inaccessible.

A Quiet Exhaust.

A very large silencer, placed in front of the underscreen, and having a long flat pipe, renders the exhaust reasonably quiet, and the enclosed release valve is practically noiseless when in operation.

The cooling of the engine appears to be extremely efficient, and, though our ride was too short to allow of a long run on full throttle, we were assured that it is practically impossible to dry up the engine, and-we certainly saw no indication of this trouble. In this connection a rather interesting feature is noticeable, in that the top fin is formed by a detachable copper rib, held' in position by a plug in the centre of the cylinder head. This serves a double purpose, in that it assists the cooling of the most vital point on the engine, and also saves the fracture of the top rib, which is a rather common occurrence when cast iron is used.

It is Messrs. Hanwell's intention to market the little machine at a reasonable price, though no definite figure can be given at the present moment. Deliveries will commence in January.

The works are being carefully laid out for mass production, and the jig work is very well advanced.

The Motor Cycle, October 9th, 1919. pp 384-385

If you have further information or a query related to this page, please contact us