1888 A revised version, named the Petrol-Cycle ran. It had a four-stroke engine and a reduction gear to allow it to run at 600rpm. It was water-cooled with coil ignition and a jet carburettor supplied by a float chamber.

1889 It was first used and called an Inspirator by its designer.

1890-1897 The original design could only carry one person, so a later version was designed to carry three people - two at the front, between the twin wheels, and the driver at the rear. This is thought to have been a Bolle built by Humber and fitted with the Butler engine. At that time, British legislation was very restrictive and although the clever design was advanced for the era, its backers moved on to other fields. The patents were bought by Lawson Co but never progressed any further.

Butler is credited with inventing or developing the spark plug and coil ignition, magneto and the spray jet carburetor, as well as the word 'petrol'. His Petrol-Cycle was broken up for scrap in 1896, the few remaining pictures of this first British motorcycle are in the Science Museum in London.

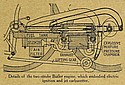

Details of the two-stroke Butler engine, which embodied electric ignition and jet carburetter.

Detailed drawings of the original Butler patent: Science Museum Group Collection

A pioneer designer and his three-wheeled runabout of 1888.

Side view of the "Petrol Cycle," showing its curious construction

IT is not generally known that a little petrol-driven tricycle was built in this country in the year 1888, and that the engine was of the two-stroke type. This was the Butler petrol cycle, of which the first design was exhibited at the Inventions Exhibition in 1885, while the provisional patent is dated 1884 - thirty-four years ago.

Truly one may say that this was the first cycle car, and it is remarkable that it had electric ignition, clutch control, an epicyclic gear, and stub axle steering such as is common practice on cars to-day.

A study of Mr. Butler's pioneer machine is most interesting, and the mechanism needs very careful investigation if all its ingenuity is to be appreciated.

The method of working out the two-stroke principle is different from conventional practice to-day. From a pressure diagram before us, it is clear that a more perfect exhaust stroke is obtained than even in a four-stroke engine, while the charge is only transferred after the piston has reached' the top of the stroke. The main advantages are perfect exhaust and perfect charge, so far as the working cylinder is concerned. The disadvantage of this principle would be an unduly high receiver pressure needed for the transfer. . 1

In all it appears to be a system which, if taken up again and modernised, might give good results, particularly as regards the thermal efficiency.

The Automobile Engineer of March, 1916, gave the following description as provided by the inventor:

"There are two cylinders, one at each side of the driving wheel, and arranged acting away from the driving cranks, in order to work with an unusually long stroke and to have the front ends arranged as compressing pumps. The pistons are connected by rods to cross-heads, and these by return connecting rods of oval section tapered steel tubes to the cranks, which are at 180°. Each cylinder is self-contained, and draws in and compresses mixture at the front end into a pressure chamber arranged underneath, a jacket surrounding the pressure chamber being utilised to heat the mixture. The cylinders are 2 1/4in. diameter by 8in. stroke, and the mixture, compressed to from 15 lb. to 30 lb. per square inch, according to throttle opening, is admitted to the explosion end of the cylinders for 2 1/2 in. of the power stroke, when it is cut off by the rotary valve and immediately ignited by a wipe contact spark, produced by a spring point extending some 3in. from a plug screwed into the cylinder cover.

A pressure diagram, which appeared in our sister journal The Automobile Engineer, was produced when the motor was running at about 300 r.p.m. and with the throttle fully open. From this it was seen that the pressure was between 20 lb. and 30 lb. for the first 2in. to 3in. of the stroke, rising to 100-120 lb. after the crank had moved to about 60° of the power stroke.

The Method of Starting.

"At each end of the cylinders there is a balanced tapered rotary valve driven at half speed by a sprocket wheel and chain. Between the rotary valves and the pressure chamber there are two plug throttles, and a third plug to control the admission of mixture from the carburetter to the compressing end of each cylinder. The purpose of the three plugs is to enable the motor to be used as a compressor while pushing it along the road for a hundred yards or so to charge up the cylinders, after which operation the plugs are moved round a few degrees to start the motor under air pressure with the driving wheel raised off the ground. Immediately on the chambers commencing to fire, the plugs are moved round to the third position to place the compressing ends into connection with the pressure chambers.

"In practice it was found that the motor would not work slowly enough to propel the car along unaided at the start, i.e., when the driving wheel was lowered to the ground, and the car had to be pushed along at a running speed until both cylinders picked up. The motor, however, would run very satisfactorily with the driving wheel running on a pair of grooved pulleys when allowed to speed up to about 250-300 r.p.m.

"The current for the ignition was at first obtained from a dynamo magneto, but as this took up so much of the available power a primary battery was substituted. At first a Bunsen nitric acid battery was used, then a bichromate of potash, and finally a silver-carbon plate battery known as the Shancheef, really a modification of the silver-copper Smee battery. The carburetter was placed forward, just over the petrol tank, and was within reach from the seat for adjustment of the petrol feed by a pin valve; this carburetter had a jet feed and automatic air plug to maintain a constant mixture for different positions of the throttle and for varying speeds. In the trials Pratt's gasolene was used, although the motor would run on commercial benzolene, but did not start so quickly on the heavier spirit.

"After a considerable amount of experimental research with the motor arranged to work on a pressure admission two-stroke cycle this was decided to be unsatisfactory, and the motor was altered to work four-stroke, when the pressure chambers and the valves at the compressing end of the cylinders were cut out, and the valve at the explosion end altered to admit mixture at alternate forward strokes instead of at each stroke as formerly. An epicyclic transmission gear was also fitted in the motor to speed up to 400-500 r.p.m. when running along the road at from eight to ten miles an hour. The four-stroke motor ran much better, and after being first started by a handle on one of the cranks, with the driving wheel raised from contact with the ground, the car could be quite easily started from the seat by a foot lever at the right-hand side of the footboard. This method, although seemingly strange, really worked very well, as the driving wheel could be let down quite gently with the toggle lever control.

On the left side of the footboard was a second foot lever for the brakes on the front steering wheels. These were carried by stub axles swivelling in sockets, and were connected for the three wheels to focus to one point when steering in either direction. The cylinders were jacketed and connected by large pipes to a water tank arranged over the driving wheel, which, although heavy, appeared to keep the cylinders from overheating. This little car, although of short wheelbase, and with wheels only 32in. and 30in in diameter, weighed with oil and water 400 lb. After being altered from two-stroke to four-stroke, the ignition was changed from wipe spark low-tension to high-tension, with a hub of a new driving wheel, which now allowed sparking coil and rotary distributer."

The Motor Cycle, January 9th, 1919.

See also: Daimler

Unrelated to Chris Butler

Sources: Graces Guide, The Motor Cycle

If you have further information or a query related to this page, please contact us