This article first appeared in Lincolnshire Life magazine in March 1986 and is reproduced with their kind permission.

Researched by Roger Brown

WHEN James Kirby began selling bicycles in Lincoln, cyclists were loud in their praise of his 'Lincoln Elk'. According to his catalogue, James Kirby was making cycles in 1882, though the early history of himself and his partner Edwards is unclear.

The firm began in the Ordinary or Penny Farthing period and saw the advent of the diamond framed Safety, and by the turn of the century Kirby and Edwards had established an excellent reputation. Their premises, which they called 'showroom and manufactuary', were in 4-5 Broadgate, Lincoln, on the site of the present GPO Telephone Exchange.

Their Lincoln Elk Cycle was a well deserved success. being built to a high quality and was offered for a little less money than nationally advertised competitors. The standard colour of these machines is believed to have been 'Lincoln Green'. It had a light but very strong frame, at a time when many machines were heavy and cumbersome. The radially spoked wheels carried solid rubber tyres, less comfortable to ride on than pneumatics, but at least they couldn't puncture. The single brake was operated by a handlebar-mounted lever to the right, and was of the 'spoon' type, bearing directly on the front tyre in front of the forks. Slim mudguards, a large comfortable saddle and an oil front lamp completed the specification.

Then manufacturers experimented by fitting small petrol engines to their machines, to give the motor cycle. Most designers favoured mounting the engine within the diamond of the frame and as low down as possible to improve stability. But the standard frame was of insufficient strength and it wasn't long before special heavy-duty machines were being built, with an altered frame shape It was into this design climate that James Kirby launched his first machine, it was immediately successful, being comparatively cheap, simple and reliable, and was in essence a heavy-duty pedal cycle with a power unit added.

Around the turn of the century James Kirby appears to have been trading alone. the name Edwards disappearing after about 1901. By this date Kirby would have been 63 years of age. In the booklet listing his 1920 models. he recalled that in the summer of 1902 he was asked to make 'Motor-Bicycles of the same reliability and sterling

Kirby's 'showroom and manufactuary' in Broadgate.

good qualities as my Bicycles were acknowledged to be, and at a proportionately low cost'. Thus in autumn that year the first Lincoln Elk Motor Cycle appeared.

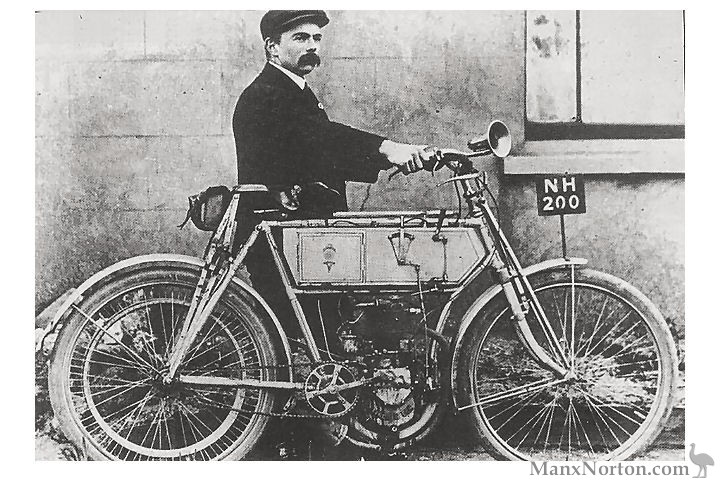

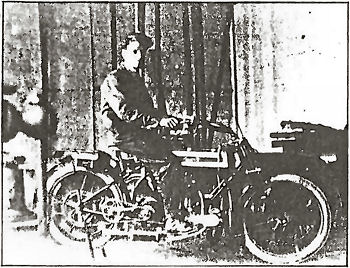

1905 Model

The 1905 2¼ hp model had a cycle based loop-type frame, though of much sturdier construction with the addition of a second crossbar to aid frame stiffness. The engine was a side-valve four-stroke single with a horizontally mounted sparking plug. The engine would almost certainly have had plain bearings and may have been fitted with an automatic inlet valve. In this arrangement the valve was kept closed by the pressure of a light spring and opened by cylinder depression caused by the downward movement of the piston. The carburettor was controlled by a jointed-rod linkage from the lever at the front of the petrol tank.

Beside containing petrol, then priced at between 9d and 1s a gallon, the large tank located between the two crossbars also contained a reservoir for oil. The engine is a 'total-loss' unit in which oil enters the crankcase where it is distributed by splash to the bearings and eventually passes up the barrel to the combustion chamber where it is consumed. Supply to the engine was dependant on the hand pump located on the tank top. There was also an exhaust valve lifter, sometimes called a de-compression lever. Its purpose was to relieve cylinder compression when starting and pedalling off, and to reduce power from the engine as an aid to low speed manoeuvring.

The De Dion ignition system which was introduced in 1895 seems to have been adopted by Kirby in his first motor-driven Lincoln Elk's. It comprised an induction coil, an accumulator or dry cell and a contact-maker, and became standard on cars and motor-cycles for several years. To the rear of the petrol tank was a small hinged panel containing the coil and the accumulator, which would be a small 4-volt 20amp hr unit in a celluloid case. This case was fragile and liable to breakage from the vibration, so acid leaks were always a hazard. In front of the panel was a stout lever working in a quadrant and connected by rod to a device at the front of the engine. This was the contact-maker and was operated by a half-time engine shaft to induce a high-tension current in the secondary circuit at the required moment, which was then carried to the sparking plug. The lever would advance or retard the moment of ignition.

Power was transmitted to the rear wheel by a V-section belt, which Pioneer motor-cyclists remember as slipping furiously in wet weather, and the wheels were shod with pneumatics of large section. These would have softened road shocks a little, even though inflated to quite high pressure by the pump mounted above the top crossbar.

The Road Act of 1903 increased the maximum permitted speed on public roads from 12 to 20mph from 1904, but this machine would be able to just exceed that. Even so modest a speed makes the stirrup braking arrangements, fitted to both wheels and working on the inside of the wheel rims, seem optimistic to say the least. Stirrup brakes were poor in dry weather and useless in the wet. The bicycle pedals and chain were connected to a 'free-wheel' at the rear hub and were used in starting the machine and in giving assistance on difficult going.

It seems likely that James Kirby started his business career by dealing in cycles, probably Penny Farthings and then the later Safetys. As the cycle industry developed many firms became component suppliers, making everything from frame lugs to a complete machine which only required the seller's name applying to become another 'new make'. As frame making was not too difficult an art it may have been that Kirby began by making frames, or by having them made, to which he then added 'bought-in' parts and sold under his own name.

The success of his Lincoln Elk bicycles allowed Kirby to set up a

Page 20, LINCOLNSHIRE LIFE, March 1986

1905 2¼ hp model with owner William Crawford, blacksmith of Aby, c.1910.

largely independent operation for the manufacture and sale of his machines. It was his repeated claim that all but items such as carburettor, tyres and (later) magneto were made at his factory in Broadgate.

Before World War I there were two models of motor-cycle available, alongside the continued production of pedal cycles. These were 402cc and 499cc single cylinder machines, believed to have been designed by James Kirby.

The photograph of the premises, which faced St Swithin's Square, is believed to show James Kirby standing at the doors to the left, the date about 1900. The main windows contained machines for sale, one with an oil front lamp, with a show-card for Dunlop detachable tyres. The single window to the left of the shop doors contained various items of bicycling paraphernalia, spares, accessories and an advertisement for White's Electrine Cycle Oils.

The Trader Handbook and Diary for 1915, (a motor and cycle traders' publication), lists the full Lincoln Elk range with prices and also includes the machines being offered by F. Hopper & Co. of Barton on Humber, makers of the Torpedo motor-cycle Where a similar model exists in both ranges, Hopper's prices are included in brackets for comparison: LE 6hp £55. LE 4¼ hp £46. LE 3½ hp £35. (Torpedo £46) LE 3hp £31 10s. LE 2¾ hp £28. (Torpedo £38 16s.)

One of the last 1916 lightweight 23/4hp Model C.

Gearing was by no means universal on motor-cycles, though some way of multiplying the power output of the engine was beginning to be expected. Kirby's answer was his patent two-speed gear. In the 13th November 1919 issue. The Motor Cycle magazine briefly reviewed 'this unique form of two-speed gear', and seemed enthusiastic. The gear unit was mounted on a countershaft, chain driven from the nearside of the engine and located between it and the rear wheel. On this shaft were two contracting bronze rings which were controlled by a lever on the nearside of the tank, operating in a quadrant. With the lever in a central position a 'free-engine' or neutral was obtained, while moving the lever backwards gave low speed and forwards gave high. Drive to the rear wheel was by chair? on the offside for low speed, with belt on the nearside for high.

Post-war range

The post-war Lincoln Elk range comprised three models. The 'tiddler' was the Lightweight 2¾ hp Model C. In standard form it weighed 130lbs and the engine was a special lightweight Lincoln Elk unit with dimensions of 76mm x 77mm giving a capacity of 349cc. it was claimed to be very flexible, aided no doubt by its ample flywheels. Kirby advertised that both inlet and exhaust valves were mechanically operated and interchangeable, being of large diameter. Specially strengthened timing wheels were also mentioned, each valve having its own cam and with independent rockers. The magneto was front mounted and driven by a chain enclosed in an aluminium case, while the carburettor was by Brown and Barlow. Final drive was by a ¾ inch V-belt and in standard trim gearing was by adjustable pulley.

After 1908 the principle was improved to allow the gear variation to

Page 21, LINCOLNSHIRE LIFE, March 1986

Cyril Clark on a newly completed Model B.

be effected with the machine in motion. On this model for an extra £10 an Albion 2-speed gear could be specified while. for £5 more it could have a clutch and kick starter as well, with gear selection by a tank mounted lever working in a quadrant.

In common with other machines of the period, the Lincoln Elks were long and low, with a saddle height of 30 inches in all three models. This promoted stability and with the handlebars reaching well back, a comfortable, upright seating position was available. A long fork 'trail' angle, and a wheelbase of 50 inches in the Model C, made for easy straight line control, while Druid pattern front forks would absorb most road shocks and provide a reasonable ride with quite precise steering.

The stirrup brake was to be found at the front wheel operated by a handlebar lever, while at the rear a belt rim brake was controlled by foot pedal. The 26 inch wheels carried Palmer motor-cycle tyres, with a hand pump mounted above the fuel tank on the top frame tube.

Kirby claimed that this machine would run 120 miles to the gallon, giving a range of 150 miles with the 1¼ gallon capacity tank, with sufficient lubrication for 400 miles running, though this still required the rider to apply himself to the tank mounted oil pump occasionally.

The saddle was a comfortable Brooks 'B 150' with buffer springs. a most necessary consideration as roads even then were by no means smooth, even in town. A swing down stand was supplied. which pivoted below the rear wheel spindle and gave firm support to the machine, useful when mending the inevitable punctures. Aluminium foot boards were popular for many years before being superceded by footrests. A most useful accessory was the carrier mounted over the rear wheel. This could be modified to take a small pad to make a pillion or 'flapper' seat. In 1919 this model was offered at £54, but by 1920 it had increased by 10%.

A lighting set was not included as standard on any of the three models listed. The new owner would have fitted an Acetylene generator and lamps. in which a container holding dry Calcium Carbide received metered drops of water from a reservoir above.

This made Acetylene gas which was piped by rubber hose to the various lamps, where it was ignited at a burner having a reflector behind and a lens in front.

Middle of the post-war range and arguably the most popular was the Model B. This was of 4 ½ hp, again with a single-cylinder side-valve engine but having dimensions of 89mm x 96mm, giving a capacity of 597cc. Both this engine and the V-twin Model A featured hard phosphor bronze to all bearings. At 280lbs this machine was no lightweight. The transmission included Kirby's 2-Speed Countershaft Gear, where the knob for the change-speed lever was above the petrol tank, while a 1 inch rubber and canvas V-belt carried the drive to the rear wheel.

The machine's ability to be kick-started with the rear wheel on the ground was specially referred to, and the frame had a wheelbase four inches longer than the model C, with Druid spring front forks. The same braking arrangements as for the smaller model were used as were the 26 inch wheels, but fitted with 650 x 65 heavy Palmer Cord motor-cycle tyres. This machine could achieve between 60 and 70 miles per gallon drawn from a 2-gallon tank, with an oil capacity sufficient for 200 miles. A Brooks 'B170' large size saddle with buffer springs looked after rider comfort. The nett cash price with 2-speed gear was £100, but this too was increased by 10% for 1920.

By this time motor-cycle manufacturers would usually have a big V-Twin in their range. James Kirby's V-twin was the 6hp Twin Model A. Weighing 285lbs, it was only 5lbs heavier than the Model B, which made it very light (or the Model B very heavy). The twin's dimensions were 76mm x 85mm which gave a capacity of 770cc. The Model C had a bore of the same size, so possibly Kirby used two Model C cylinders and simply lengthened the stroke for his V-twin. Again, the machine used Kirby's 2-Speed Gear and Druid spring front forks, and it had a 55 inch wheelbase. The nett cash price was £115 with 2-speed gear in 1919.

These three models comprised the range of James Kirby's Lincoln Elk motor-cycles up to 1920. They were all pre-World War 1 designs which were relatively simple and reliable.

After demobilisation from the RAF [1], Cyril Clark joined Kirby's in 1919, having previously been a Ruston apprentice. He served with the firm during its last nine months and Cyril remembers James Kirby as being in his early eighties. The working hours were 6 am to 5 pm with an hour for dinner and a breakfast break between 8 and 8.30 am. The firm was an interesting example of the way a small manufacturing business operated before mass production forced them to change drastically or close down. The work was built up on an assembly bench and the men involved went to the work to perform their various duties. The assembly area was upstairs, with a slope to the ground floor for the completed machines.

To the best of Cyril's knowledge there was no foundry on the premises, so it seems almost certain that rough castings would be 'bought-in' and machined 'in-works, and Cyril remembers a man working on a turning machine, turning up cylinders. Cyril remembers too that the premises extended about forty feet to the rear so there was a fairly large area available over the three floors. Individual people had specific responsibilities. For example, one man made the frames at a brazing-hearth in a tray on the ground floor and then enamelled the finished frames in a dipping tank. Another man spent most of his time in making up gearboxes, while a third, after erecting an engine unit, fitted it into a frame and built the machine up.

The foreman, who lived in Winn Street, supervised the operation and attend to detail fitting and final checks, prior to a road test 'on the trying hills around Lincoln', according to Kirby's booklet. Bright work plating was also done on the premises in a nickel bath. The frames were black, with a silver painted tank having a green panel. Towards the end only one model was being made. Kirby sent machines abroad, including some to South Africa, while the Wholesale agents for Scotland were the North British Machine Co. of Glasgow.

At the beginning of 1920 James Kirby would almost certainly have been in his eighty second year. This, coupled with the fact that to remain competitive new methods and designs were desperately needed, would have caused him to think very hard of the future. Over a hundred different firms were fighting for their share with two hundred different models, and so James Kirby faced the inevitable.

Cyril Clark still retains the typewritten postcard he was handed. It read: 'Your services will no longer be required after 3rd September 1920. No more work'. It was signed, James Kirby. Lincoln's motor-cycle had come to the end of the road.

Page 22, LINCOLNSHIRE LIFE, March 1986

Notes

1. The Royal Flying Corps (RFC) merged with the RNAS to form the Royal Air Force on April 1st 1918.

Source: Lincolnshire Life

If you have further information or a query related to this page, please contact us