Villiers 1938 Advertisement

Villiers 1950 Advertisement

Villiers 250cc Twin Advertisement

Villiers Advert 1950s - Lodge Sparkplugs

Villiers Engineering Ltd was a manufacturer of motorcycles and cycle parts, and an engineering company based in Villiers Street, Wolverhampton.

of Marston Road, Wolverhampton. Telephone: 21666/7/8. Telegraphic Address: "Villiers, Wolverhampton". (1937)

1890's John Marston's Sunbeam had become extremely successful, by relying on high quality of production and finish. But Marston was dissatisfied with the pedals on his machines, which he bought in.

In 1890, he dispatched his son Charles to the USA on a selling trip but included in his instructions that Charles must discuss pedal engineering with Pratt and Whitney in Hartford, Connecticut and come back with a high class pedal and the machinery for making it. Charles said that the Villiers Engineering Co. was "the ultimate fruit" of his trip to the USA, being impressed by the production system and the labour saving devices. He pointed out that "it was not possible to develop these at Sunbeamland, which had long been working on another plan, but it was possible to start them in a new factory".

1898 As a result of the tour John Marston bought a small Japanning works based in Villiers Street, Wolverhampton that had belonged to Edward Bullivant, a producer of japanned ware on quite a large scale. Under the direction of Charles, the company made cycle parts for the Sunbeam product. As the factory was producing more parts than Sunbeam required, it sold components to other manufacturers.

1902 was a momentous year for Villiers. Firstly, John Marston sold the company to his son Charles for £6,000 on a loan against future profits. Secondly, it developed and patented the cycle free-wheel, which every cycle manufacturer required. The production of free wheels reached its peak just after World War II, as the company produced 80,000 per week or 4 million per year.

1902 Frank Farrer, who was then the manager of the Palmer Tyre Company's Coventry depot was appointed as sole agent for the sale of the surplus pedals. Farrer had many connections with the cycle trade, was a good engineer and a great salesman and was to become the driving force in Villiers. So quickly successful was this move that Frank Farrer joined Villiers full time in 1902 and the factory was employing 36 men.

1911 Engine production commenced, but sales were slow until 1913 when the first two-stroke was produced.

After the Great War, Villiers engines were supplied to: Atco Mowers, Clifford Cultivators, Howard Rotavator, Sun motorcycles, James motorcycles, Greeves motorcycles, Francis-Barnett motorcycles, Norman motorcycles, Ambassador motorcycles, DKR motorcycles, DMW motorcycles, Dot motorcycles and Panther (P and M) motorcycles, among many others.

1919 Charles Marston left the active day to day management of the company. He remained as Chairman but appointed Frank Farrer, as Managing Director.

Fitted to F-B Model 10 Pullman, Monet-Goyon BL350, La Mondiale and MT (Austria)

1937 Listed Exhibitor, British Industries Fair. "Villiers" Stationary Engines from 1½ hp to 4hp, for industrial purposes. A full range of Steel Stamping and Non-Ferrous Castings. "Villiers" Cycle Products, including Freewheels, Speed Gears, and "Villiers" Motor Cycle Engines. (Stand Nos. D.825 and D.724)

1937 Manufacturers of two-stroke engines and accessories. "Villiers" Two-stroke Engines and Accessories.

1956 Villiers produced its two millionth engine and presented it to the Science Museum in London.

1957 Villiers absorbed J. A. Prestwich Industries Ltd, makers of the JAP engines.

1961 Manufacturers of internal combustion engines, including the "Villiers" two-stroke and four-stroke light internal combustion engine. Also manufacture cycle components, freewheels, magnetos, and carburettors.

1962 The company were claiming that: "jointly, the two companies produce a vast range of two-stroke and four-stroke petrol engines and four-stroke diesel engines from 1/3rd to 16 b.h.p. These are the engines which power many of Britain's two-stroke motorcycles, scooters and three-wheelers and the great majority of the motor mowers, cultivators, concrete mixers, generating sets, elevators, pumping sets. etc."

1965 The company was taken over by Manganese Bronze.

1966 Together with AMC, the company became part of Norton Villiers. At this point, Villiers stopped supplying engines to outside companies. Production of the Villiers engine ceased in the UK, but continued in Madras, India.

In 1999 Villiers Plc acquired the healthcare company Ultramind and renamed the company Ultrasis.

The Argus, Fri 9 Nov 1956

New engine this month Two new 250c.c. Villiers engines have been announced for 1957, a single, starting in November, and a twin which will be available from January 1. For scooters, a 197c.c. model with built-in electric starter and fan cooling came into production in August, and another 150c.c. scooter engine, without starter, will become available next month. Smallest in the range are 98c.c. units with single speed for autocycles, or with two speeds for either hand or foot change. The rest of the range includes 150, 175, and 197c.c. units, with gearboxes up to four speeds.

Trove NLA

Ten Villiers Engines For New Season The Villiers Engineering Co. Ltd. of Wolverhampton, has announced that its 1954 range of two-stroke motor cycle power units will total 10 models, comprising one of 98 c.c., four of 122 c.c., four of 197 c.c. and one of 225 c.c.

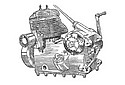

The outstanding model is undoubtedly the new Mark 1H 225 c.c. unit, which was first announced in connection with the James programme for 1954. An entirely new Francis-Barnett 'Cruiser' has been designed for the engine, and several other lightweight manufacturers are known to be interested. With its clean, symmetrical lines the Mk. 1H is the equal in appearance of certain Continental designs which have been held up as examples in the past. The crankcase, primary chain case, gearbox and electric housing blend into a streamlined egg-shaped unit, and the carburetter is totally enclosed in a cowling with remote tickler and built-in air cleaner.

Of 225 c.c. (63 x 72 m.m.), the engine has a compression ratio of 7:1 and is said to develop 10 b.h.p. at 4,500 r.p.m. Internal gearbox ratios are 1, 1.32, 1.81 and 3.06:1, and top gear with the recommended sprockets is 6.07:1.

Crankshaft A departure from standard Villiers practice is the built-up crankshaft assembly, which has circular webs forming internal flywheels. This change was necessitated by the reduction in size (and hence flywheel effect) of the flywheel generator to avoid excessive bulk of the stream-lined side-cover. The reduction in size has been effected by eliminating the ignition coil, condenser and contact breaker from the flywheel assembly and re-locating them outside.

This view clearly shows the clean, Continental-fashion lines of the Villiers Mk. 1H 225 c.c. power unit. This view clearly shows the clean, Continental-fashion lines of the Villiers Mk. 1H 225 c.c. power unit. Each mainshaft runs on two substantial ball bearings, and it is claimed that this rigid support of the crankshaft results in a very smooth power delivery. The forged steel connecting rod has a roller-bearing big end, using two rows of ¼ x ½ in. rollers. A steel-backed, bronze small-end bush is employed.

The flat-topped piston has two pegged rings, and bronze bushes in the gudgeon-pin bosses. Both the cast-iron cylinder barrel and die-cast light-alloy cylinder head are deeply finned; the spark plug is located towards the rear of the hemispherical combustion chamber. Anti-ringing bridges are cast in between the upper fins on the barrel at front and rear.

Gearbox

A Villiers-built four-speed gearbox is bolted to the rear of the crankcase, giving accessibility to the cluster and change mechanism without requiring the crankcase to be split. A neat gear-position indicator is situated above the kick-starter, which has an unusually robust ratchet mechanism. A pre stretched endless primary chain and cork-faced multi plate clutch run in oil.

The electrical system has several interesting features. The flywheel generator now has only four windings, one pair providing ignition current and the other pair charging the battery by rectifier. As the ignition windings give more voltage at high speeds than is required for ignition purposes, an additional parallel circuit is taken from the lead between generator and ignition coil to feed the rectifier. Thus, as soon as the voltage from the ignition windings exceeds the back E.M.F. of the battery, the 'surplus' voltage is by-passed and assists the charging of the battery, it follows that ignition voltage remains substantially constant at all speeds.

A key-operated lock is flush-fitted on top of the crankcase to the right of the cylinder. This is not an ignition switch in the normal sense. but a thief-proof device, since in the 'off' position it earths the primary ignition circuit so that the engine cannot be started. Only one alteration has been made to the other engines in the Villiers range; this concerns the contact breaker, for which an eccentric-type adjustment has been introduced. Manufacture of the Mk. 2F 98 c.c. autocycle unit has been abandoned in favor of the Mk. 4F, with its two speeds and streamlined lower half. Of the four 122 c.c. and 197 c.c. units, two of each are competition models. This leaves the standard 12D 122 c.c. engine, the utility 13D of the same capacity, the three-speed 8E 197 c.c. unit and the four-speed 8E/4.

Courtesy Trove NLA

Sources: Graces Guide, Trove NLA

If you have further information or a query related to this page, please contact us