Bradbury and Co. built motorcycles from 1901 to 1924 and introduced one of the earliest forms of variable gearing, using manually adjustable pulleys.

1901 The first machines had a Minerva engine suspended from the down tube of a standard bicycle.

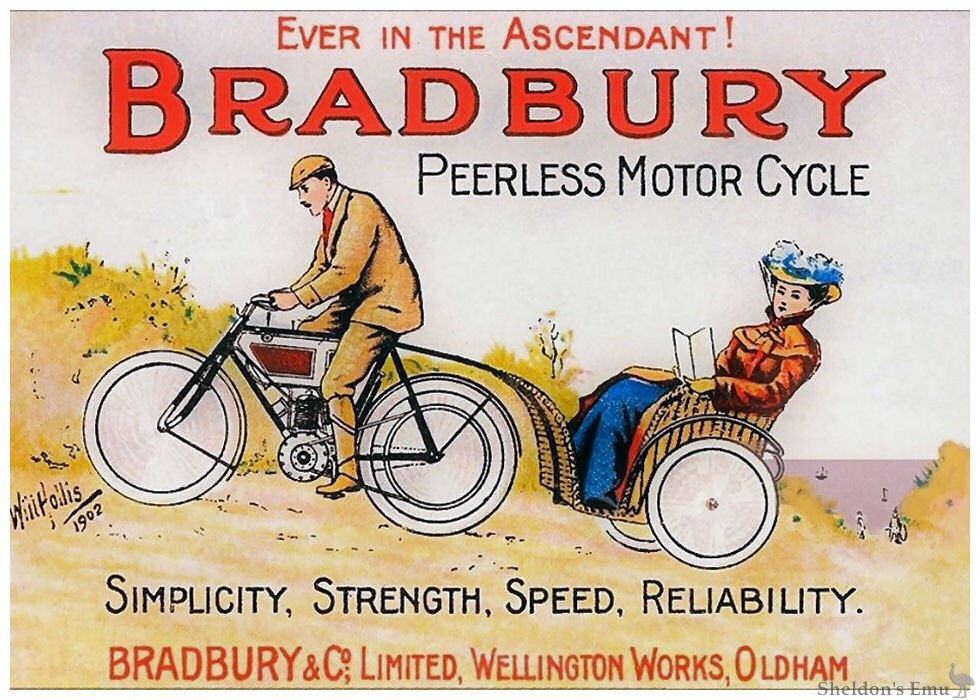

1902 Late that year they produced machines built to the Birch design. This had the crankcase cast around two of the main frame tubes. In other respects they were similar to the new Werner design and were fairly primitive. The principal model, listed as the Peerless, had a 2.5 hp engine. A lightweight was also listed and this had a Clement-Gerrard engine inclined above the frame down tube. It drove a counter-shaft which was mounted ahead of the bottom bracket, it then went to the rear wheel and both drives were by chain. Other than that it was no more than a heavy-duty bicycle.

1903-1908 The model continued with a few modifications and the crankcase cast to the frame. Various power outputs were available as well as a tandem backseat frame. This was a pillion seat with handlebars. There was also a forecar with a 4hp water-cooled engine and chain drive.

1909 Still of the same construction, but now with sprung forks, the firm standardized on a 3.5hp model - followed by transmission models.

1912 Variable gearing was introduced.

1913 Late that year 3½ h.p. flat-twin model appeared. This had its magneto mounted on top of the crankcase, a three-speed chain-driven gearbox, the choice of chain or belt final-drive and drum rear brake.

1914 A 6 h.p. V-twin model was added. This had a three-speed gearbox, all-chain

drive and drum rear brake.

Bradbury 1914 Models

1915 The models continued and the single was rated at 4hp.

1916 The V-twin and the single, with various transmission options, were available that year. Throughout World War I those models remained in production for service use.

Bradbury 3½ h.p., 68x68.7 mm., 499 c.c.

The cylinder heads of the Bradbury are detachable, which enables the whole of the cylindrical part of the cylinder, including the horizontal cooling flanges, to be machined. The cylinder is then nickel plated to prevent rust. This gives it a very distinctive appearance. The valves are side by side and operated by adjustable tappets. A B. and B. carburetter is employed, and Best and Lloyd semi-automatic lubrication. The Bradbury flat twin was introduced just prior to the war, and only a limited number are in the hands of motor cyclists.

1919 After the war, that line still continued with the addition of a 2.75hp, two-speed single with chain-cum-belt drive.

1920 Just three models were available, as the 4hp single was dropped.

Bradbury 1920 Models

1922 The smallest model had transmission options.

Bradbury 1922 Models

1923 That model was now only available with three speeds and chain drive.

1924 They were now down to just two models, both of which had been redesigned and enlarged. Early that year the firm failed and production came to a close. The stock was sold on to an ex-employee who, for some years, sold spares and built machines from those parts.

Note: The original machines were termed "Peerless" in 1902-1904.

Wellington Works, Oldham

1852 - Bradbury & Company Ltd. of Oldham was the first company in Europe to manufacture sewing machines. Production began in 1852 at The Wellington Works and by 1887 the firm's annual output was between 26,000 and 30,000 units. They also produced machine tools, bicycles and motorcycles as well as prams and children's toys.

1874 - Bradbury and Co was established on 5 May, to acquire the business of sewing-machine makers of the firm of the same name, and the business has since been extended to cycle and tool manufacturing.

By 1890 around 600 factory staff were employed with a further 800 at 60 depots.

By 1898 Bradburys had produced its first motorcycle and, although sewing machines continued to be the firm's main product, a vigorous and sustained effort was made to enter the automotive industry after 1900. As well as motorcycles, a prototype motor car was developed but did not enter production.

In 1903 Bradbury were making large turret lathes.

At the end of 1905, when the company employed around 1,500 workers, a range of motorcycles was available.

By 1914 Bradburys were reducing their reliance on the sewing machine market through diversification and had achieved some success in the motor industry. The firm was experienced in mass production techniques and was probably set to realise the fruits of previous years development of motorcycles and quite possibly cars as well.

WWI - During the war Bradbury & Company Ltd. supplied motorcycles and bicycles to the British forces. They probably also supplied machine tools to munitions factories and in all likelihood produced munitions themselves. After the war the company reintroduced it's range of sewing machines and other products but by the end of 1923 were experiencing financial problems and it is believed that production had been seriously curtailed.

1924 - Bradbury ceased all production in 1924, at the lowest point of the post-war slump. In the sewing machine market they were in competition with the Jones Co of Audenshaw as well as the Scottish subsidiary of the American firm Singer.

1929 - Eventually, Bradbury & Co. Ltd. was officially dissolved in May 1929.

Sources: Graces Guide, The Motor magazine, et al