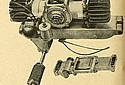

The transfer pipe, which forms the lid of the crank case and support for the magneto, is shown detached. Both cylinders of this engine fire together and at every complete revolution.

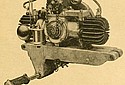

Note how the aluminium silencer forms a bed plate for the engine.

The back cylinder of the new twin Connaught. On top is the transfer port, and directly below lies the exhaust port, while, below the flange, the comer of the inlet port can be seen.

As regards two-stroke motor cycle engines, the new horizontally opposed twin Connaught marks a new epoch. So far some difficulty has been experienced in constructing air-cooled two-stroke engines having a cylinder capacity exceeding very moderate limits, but there would appear to be no reason why this limit should not be approximately doubled by employing a twin. Ill the case of the Connaught this has not yet been done, as the new engine has a bore and stroke of 60 x 60 mm., but it must be realised that, although the crankshaft impulses occur at the same intervals as would be the case in a horizontal twin four-stroke, yet both cylinders fire simultaneously, and, therefore, double the number of explosions take place. Thus, the balance is as good as possible with a twin engine, and the torque is as good as with a four-stroke horizontal twin.

The cranks are set at 180°, and carefully balanced, the shaft running on ball bearings with plain compression retainers. Both cylinders project a long way into the aluminium crank case, the inlet port being formed in the casing of the rear cylinder.

Both cylinders and crank case are bolted firmly to a stout aluminium casting which forms a combined bedplate and silencer, and is rigidly attached to the frame at both ends. This bedplate bolts directly to the exhaust ports, and thus no exhaust pipes are employed. The lid of the crank case, which also acts as a magneto platform, is formed by part of the transfer pipe casting which lies along the top of the engine. This transfer pipe includes a very unusual device, consisting of a rotary throttle sleeve in the rear cylinder lead. The object of this is curious.

All two-stroke riders know that when running light, either downhill or with the clutch out, their engines develop a tendency to four-stroke, and it has been found that by cutting out the rear cylinder on the Connaught by means of the beforementioned throttle the full charge passes to the front cylinder, which continues two- stroking regularly, giving the same number of impulses as though both cylinders were in action.

The magneto problem for an engine of this type requires some consideration, as two sparks have to be generated simultaneously, but in engine we inspected the trouble been overcome by a special U.H.

Lubrication is by petroil, and frame and fittings, with the exception of the special engine fixings, are on standard Connaught lines. Photographs of the new engine appear on the opposite page.

The Motor Cycle, December 24th, 1914. p706.

If you have further information or a query related to this page, please contact us