This section has been compiled for those interested in the "Workings" of the Legendary J.A.P. Engines and includes sections from the original Handbook and Spares manual. You can find helpful Tuning Tips should you be fortunate enough to own one of these magnificent engines.

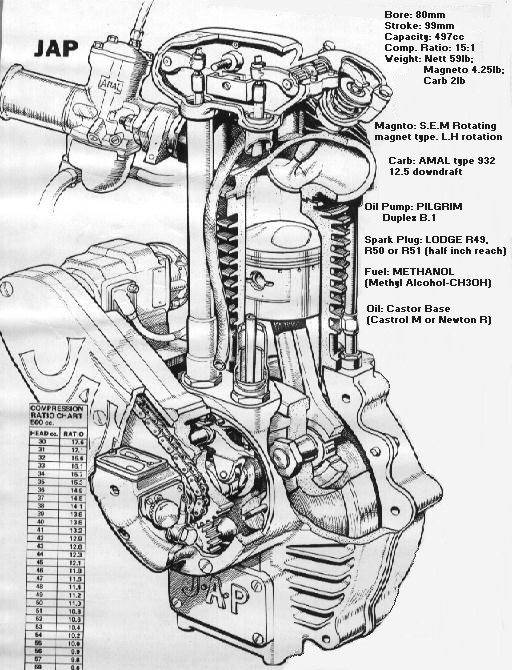

NOTE: All specs given here are as from the standard 500cc (Type 4B) Speedway Engine. DISCLAIMER: Whilst every care has been to taken to ensure correct Data, expert advice should be sought prior to any adjustments made from this information.

Magneto Ignition Advance: 35deg. before TDC (15:1 Comp. Ratio)

Piston Clearance: .006" at bottom of skirt on thrust faces (at right angles to Gudgeon pin).

Piston ring Gap: .008" (minimum)

Tappet Clearance: .002" (engine warm)

Magneto Contact Breaker Points: .012"

End Float Of Con Rod between Flywheels: .010" to .020"

End Float of Flywheels in Crankcase: .010" to .020"

End float of Camwheel: .003"

End Float of Cam Levers: .003"

End Float of Rocker Levers: .002"

Exhaust: Opens 65 deg Before BDC - Closes 34 deg After TDC

Inlet: Opens 44 deg Before TDC - Closes 62 deg After BDC

Exhaust: Opens 80 deg Before BDC - Closes 50 deg After TDC

Inlet: Opens 60 deg Before TDC - Closes 80 deg After BDC

*Note*Due to increased overlap on this special cam,

care must be exercised to ensure that there is sufficient mechanical clearance

between valve heads and Piston Crown.

It is not recommended that this cam be used if the valve head diameters are greater

than standard.

A RACING JAP is an incredibly simple engine, and is no trouble to work on. Both steel and dural con-rods are available for JAP engines. There is no preference.

When reassembling, the con rod should have a side float between the flywheels of .010" minimum. When the flywheels have had several crankpins fitted the tapers 'sink' causing the wheels to 'nip' the con rod and this is remedied by fitting an oversize crankpin, this oversize is in length between tapers (not diameter). There are two oversizes, Part No. 11453/1 ( 1/32" longer between tapers) and 11453/2 ( 1/16" longer between tapers). The flywheel assembly must be accurately trued between centres after assembly and the crankpin nuts properly tightened.

Like the crankpin, bearing housings are also available in oversizes and when refitting, after replacement, thrust washers should be fitted to provide the flywheel assembly with an end-float of 10 to 20 thou.

Both the crankpin and timing-side mainshaft rely entirely upon their tapers for alignment in the flywheels. Make sure that the mating oil-holes align during fitting. The driveside mainshaft is tapered and keyed.

Both valve and ignition timing on JAP engines is critical. Always use a degree timing disc with a dial gauge to note valve movement. Before timing the cam, pinion backlash MUST be determined and should be l deg. For this purpose Timing Pinions, - 6 Std + 6 + 10 are available.

Reface the valves and valve seats every time the engine is dismantled. This is the secret of the JAP - no power should be lost through bad valve seatings. When assembling, always fit the push-rods first without the cover tubes. Then spin the rods to check that they are straight.

Actually two pumps, one supplies the big-end via the oil tube and this is the one furthest away from the engine, controlled by the front adjuster and it should always be set to give the maximum flow. The inner pump, controlled by the rearward facing adjuster, supplies the rocker box this should be adjusted to supply a small quantity (one drop every five seconds when ticking over).