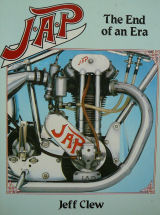

During the winter of 1930/31, some further engine and frame modifications were made. An entirely new single exhaust port cylinder head was produced which, in conjunction with a new design of piston, gave a compression ratio of 10:1. It was available as an alternative to the twin-port head, which continued in production. Some believed the twin-port head gave better acceleration, an important factor as rolling starts were being used to start races, starting gates being unknown at that time. The engine now looked even less like a 500 and could be readily distinguished from the standard racing engine as the cylinder barrel finning had been reduced to a bare minimum. It was about now that the famous JAP logo was cast into the timing cover, to replace the capital letters arranged horizontally as in the past.

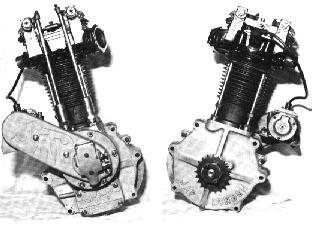

During the winter of 1931/32, the speedway JAP engine underwent some further modifications, to make it even more competitive. Some of the changes were quite noticeable externally, such as having the crankcase halves recast stiffen up the mounting lugs and provide generally a more robust assembly.

To help in this latter respect, horizontal ribs were cast integrally into the lower portion of each crankcase half. In addition, a cast alloy rocker box was used to replace the old rocker standards that were originally part of the cast iron cylinder head, leaving the valve gear fully exposed. The push rods were now enclosed within tubes, the rocker arms running on a double row of needle roller bearings, the push rods running direct on the cam levers. In order to accommodate the new rocker box casting, the cylinder head was recast with a flatter external profile, and the cylinder barrel had more generous cooling fins, the still-horizontal inlet port of the cylinder head being arranged to emerge on the nearside of the engine. The valve guides were of bronze, impregnated with oil. Not so obvious were the internal modifications, necessitated by raising the compression ratio to 12.5:1. Steel flywheels replaced their earlier cast iron counterparts, which were shotblasted, and polished on their rims. The inside of the crankcase halves was polished, too, to help lessen the effects of oil drag, a single Pilgrim oil pump still delivering oil on the total loss principle. Increased engine loadings made it prudent to increase the diameter of both the crankpin and the gudgeon pin. In order to maintain an even closer check on engine quality, it was agreed that every new engine would be brake-tested, prior to despatch.

A test procedure was devised in which each engine would run for four hours at 3,800rpm, after which it would be run on full throttle for ten minutes. It was expected that under these circumstances, each engine would record a minimum of 37.8 bhp at 5,750rpm, this being the peak of the power curve. the valve timing having an overlap of 78 degrees. Afterwards, the engine would be dismantled for inspection, then reassembled ready for despatch to the customer. By this time, all JAP speedway engines were of the single exhaust port type, the original two-port head having been dropped from production. Prophetic, perhaps, in some ways, as the starting gate made its debut during mid-1930's so that rolling starts became unfashionable.