Initially, there was no such thing as a speedway bike, everyone rode whatever they happened to have, more often than not a road bike shorn of all but the essentials which could well have been ridden to a meeting. But it soon became obvious that some machines were much more suitable than others for this type of racing.

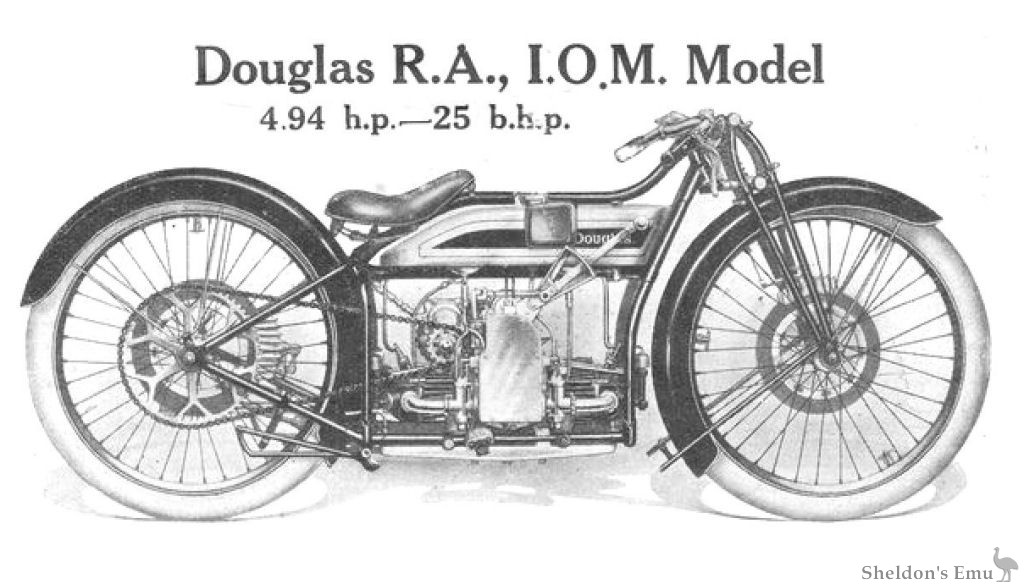

High on the list of desirables was the Douglas Twin, which had a low centre of gravity, was easy to ride, had a good power output which would respond well to tuning, and could be slid with ease on a loose surface.

Already, some of the leading Australian riders had made quite a name for themselves, Douglas mounted, by using what was basically the Les Bailey designed RA model, the type of machine on which both Freddie Dixon and Tom Sheard had scored their 1923 TT wins. It is difficult to say who was the first to use a Douglas on the dirt with marked success, though it seems probable that this distinction must be shared between Charlie Datson and his brother Jimmy. Certainly Charlie's original engine was displayed for a while in the Douglas works. But the first Riders to have tangible links with the factory were Billy Galloway and Keith McKay, who were loaned RA models when they arrived in England to ride in the Historic High Beech meeting.

Note: The R.A. derived its name from the "Research Association" brakes, an early form of disc brake in which the disc is made of friction material.

In 1909, Les Bailey (Stephen Leslie Bailey), the designer of the R.A. Douglas, conducted a cycle and motorcycle

shop in Tamworth NSW, Australia. The only racing track in existence at that

time was the Sydney Showground, where Les was an outstanding rider mounted

on an Excelsior.

Early in 1910, the urge to go overseas came over him, and on arrival, Les secured a job at

the Humber Motorcycle works as a tester. He studied engineering and earned high honours in his

exams, which led him to a position within the design office where he designed and produced the

1911 Twin Humber that was a great success.

He very quickly came under the eye of Billy Douglas who made him a very good offer to switch to the Douglas Kingswood factory and became a habitue of the Brooklands track. Les returned to Australia in 1913 taking three Douglas's with him where he won the Victoria 50 mile Road Race, and established a new record covering 62 miles in the hour.

During the War Years, Les was virtually in charge of the whole Douglas works churning out machines for dispatch riders in France. However, owing to an unsatisfactory change in management and the retirement of the senior members of the Douglas family, Les resigned and returned home to Australia in 1924.

More on the 1923 RA Douglas

R.A. Specifications

ENGINE: Vibrationless horizontally-opposed twin-cylinder. Bore 57mm x 68mm Stroke giving 346cc 2.75 model and 68mm X 68mm, giving 494cc for the 3.5 model.

CRANKCASE: aluminium casting with polished exterior, no crevices to collect dirt, constructed in two sections of great rigidity, with in cast brass bushes to take all threads and bearing housings.

CYLINDERS: fine iron castings with deep fins.

HEADS: detachable with big radiating surfaces. Valves set at 45 degrees with scientifically correct parts, internally machined throughout. Hemispherical combustion chamber giving perfect gas flow with the maximum turbulence.

VALVES: overhead with large diameter double valve springs, operated by automatically lubricated rockers, tubular pushrods and robust tappet gear.

PISTONS: special alloy with two narrow rings at top, solid centre web takes the thrust in both directions and eliminates piston wall distortion, little end bearings lubricated by pressure of oil scraped from cylinder wall on the downward stroke of piston.

CONNECTING RODS: of "H" section carefully balanced with double row roller big ends.

CAMSHAFT/CRANKSHAFT: mounted on heavy ball bearings. Special balance weights are arranged to minimise couple. All materials used throughout are special expensive alloy steels.

MAGNETO: E.L.C or other first class British make, carried above engine under the tank, protected efficiently but quickly removable without disturbing the timing of the magneto or removing the cover of the timing chest.

CARBURETTOR: Twin Douglas, Amac or Binks, according to supplies, with aluminium air box, right hand twist grip control and extra air lever.

LUBRICATION: Oil is carried in aluminium trough below the engine from whence a handlebar controlled pump feeds oil via a tank indicator to the front cylinder, lubricating by splash the rear cylinder and the engine bearings.

TRANSMISSION: Sweet running all-chain drive amply protected (Renolds or other first class make).

CLUTCH: Douglas patent single plate incorporated in the flywheel. Of smooth action and light operation it will stand a deal of abuse and is simple to adjust in a few seconds.

BRAKES: Powerful wedge type. Special alloy shoes operating on friction material rims. Quick finger adjustment for wear. Correct radial movement is afforded to both back and front shoes by semi-parallel link motion.

FRAME: Douglas design Duplex cradle construction of highest grade weldless steel tubing. Extremely low engine position, all lugs are machined from solid steel components. Lowest possible riding position.

FRONT FORKS: Built to suit the cradle frame with central spring suspension and one-piece connecting links. Hollow spindles with wick feed delivering oil to all bearings automatically.

TANK: Sturdily built supported on brackets brazed solid with the frame, provided with petrol feed wells eliminating air locks and an extra large spring-open filler cap. Rubber knee grips anchored to the sides of the tank infinitely adjustable.

From the Speedway Workshop Archive