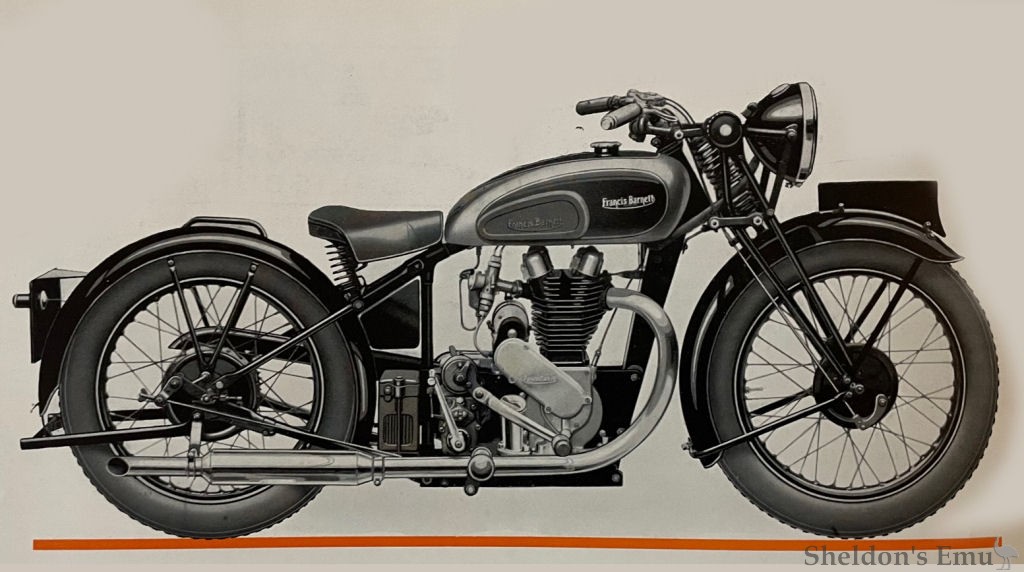

The Stag F44 and F46 of 1934-35, and the Red Stag G46 of 1936-38, were powered by a 247cc four-stroke engine built for Francis-Barnett by Blackburne. The engine had distinctive crossed pushrods.

Bob Curry writes:

Francis-Barnett had not stinted on luxury; at £48 the Stag was a good £15 dearer than such JAP-powered contemporaries as Cotton and Montgomery. But for a two-fifty of 35 years ago, it could certainly go. In a Motor Cycling road test, it reached an impressive 68 mph. And it collected a gold medal in the 1935 International Six Days Trial.

(The Motor Cycle, 22nd April, 1970)

In the design of this engine we have aimed at mechanical silence combined with high efficiency. The push rods are en- closed throughout their entire length in tunnels cast in the cylinder. The large diameter rocker spindles are carried in detachable castings.

The oil sump below the crankcase has a capacity of 42 pints. A submerged pump of the roto-plunge type supplies oil through the centre of the timing side shaft to the big end bearing. An independent feed is arranged for the overhead valve gear. The filter is removable for cleaning without draining the sump.

The front frame member, with the head, is a steel forging. A machine of high performance and distinctive character, the "Stag" carries our strong recommendation.

The illustration shows the 'Stag' engine, partly sectioned to exhibit the internal arrangement. The totally enclosed valve gear and straight valve rockers are shown, also the angle of the "cross over" push rods. The valve rockers have a direct oil feed under pressure. The upper rockers with pivot bearings are enclosed in detachable castings, each of which is provided with a removable cap for adjustment of valve clearances.

248 c.c. Francis-Barnett O.H.V. Engine. Lighting and Ignition by Miller 6 volt 36 watt Dyno-Mag

Set. 26" x 3.25" Dunlop Tyres. Electric Four-speed Gearbox. Horn.

£48-0-0

Code Word: "Stag."

ENGINE. 248 c.c. Francis-Barnett O.H.V. 68 m/m bore x 68 m/m stroke. Single Port Exhaust. Sump capacity 3½ pints, double row roller bearing to big end. Ball bearings to mainshaft.

CARBURETTER. Amal, with twist grip throttle.

GEAR. Albion four-speed; foot gear change. Ratios : 5.65, 7.6, 10.2, 16.5.

TRANSMISSION. Renold ½" P. Chains, front and rear. Primary drive enclosed in cast aluminium oil bath case.

LIGHTING and IGNITION. Miller 6v., 36w., Dyno-Mag set. 8" dia. headlamp. Ammeter and dimmer switch. 13 A.H. battery. Twist grip ignition control.

TANK. Steel, welded. Capacity 3 gallons. Finished Chromium plating with Black panels, Gold lined.

TYRES. 26" x 3.25" Dunlop.

FRAME. Special construction, ensuring great strength. Front member "I" section steel forging.

FORK. Druid. Rubber Insulated Handlebar. Hand adjusted shock absorber and steering damper.

BRAKES. 7" dia, rear and 6" dia. front.

SADDLE. Special Terry.

MUDGUARDS. 5 ¾" wide. Rear guard instantly detachable. Hand-grip fitted.

STANDS. Central prop stand, in addition to front and rear stands.

EQUIPMENT. Electric Horn, Licence Holder, Inflator, Grease Gun and Complete Tool Kit.

FINISH. Best quality Black Enamel, after Bonderizing process, and Chromium plating.

INTERNATIONAL SIX DAYS' TRIAL, 1935.

ONE "STAG" ENTERED: WON HIGHEST AWARD-GOLD MEDAL

This Trial was so severe that out of 248 starters there were 118 retirements of machines of various nationalities. The Francis-Barnett was one of only two 250 c.c. English machines to win the Highest Award.

The "Stag F/44" appeals to those riders who are especially interested in a 250 c.c. O.H.V. Model of the highest class. It has a high efficiency engine and a maximum speed well over the sixty mark. The valve gear is totally enclosed and has been designed for quiet operation and durability com- bined with high performance. The "cross over" push rods are enclosed throughout their entire length in tunnels cast in the cylinder and the large diameter rocker spindles are carried in detachable castings. The oil sump has a capacity of 3½ pints. A submerged pump of the roto-plunge type supplies oil through the centre of the timing side shaft to the big-end bearing and an independent feed is arranged for the overhead valve gear.

1935 Factory Catalogue