Mechanical oil pump driven from timing gear, a redesigned cylinder with cooling flanges parallel with ground line, and an improved kick-starter are obvious improvements noticeable in this model.

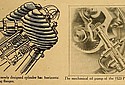

L. The newly designed cylinder has horizontal radiating flanges. R. The mechanical oil pump of the 1920 P & M.

P. & M. front forks which have been greatly strengthened. Large screw-down greasers are fitted to all bearings.

SOME important alterations have been made in the popular P. and M. since we last saw the Six Days Trial model in the company's showrooms at Berners Street, London, W.l, some few weeks ago. The most conspicuous improvement has been in the engine. The bore and stroke remain the same, namely 84.5x88.9 mm. (498 c.c), but the cylinder has been completely redesigned. It is a very fine casting, and the fins are now parallel with the ground, and there is a large air space between the valve chamber and cylinder; the ports have now a streamline form, and the valves have been enlarged.

The lubrication is effected by means of a mechanical pump, driven at low speed by a worm on the exhaust cam wheel, and oil is delivered alternately to the big end and to the cylinder. The rotating portion of the pump is in two parts, and of these, the one to which the pinion is attached has a spigot at its further end; it is also drilled to form the bore in which the plunger works; connecting with the central hole is a smaller one at right-angles, which registers with the various suction and delivery passages as it rotates. The spigot referred to engages with a slot in the upper portion of the pump, which also carries the plunger; and the upper portion isS encircled by two annular cams, forming a groove into which two pins protrude. These pins are held diametrically opposite to one another in a fixed cap at the head of the pump. The rotary motion conveyed by the spigoted section results in a reciprocating motion being given to the plunger-carrying portion through the agency of the groove in the head as the cams ride on the fixed pins.

The pump is driven at one-fortieth of the engine speed, and, on removing the cap at the head, a small screw is revealed above the cams, by means of which the throw of the plunger may be altered if desired. According (sic) as the hole at right angles to the pump bore registers with the outlets, oil is either drawn in or expelled. In the position shown in the photograph the plunger is at the bottom of its stroke, and the oil is being expelled into the lower of the two outlets, which leads to the big end. A further movement will bring the hole into a horizontal position. In this position it communicates with one of two channels diametrically opposite to each other in the outer casing. At this moment the plunger is at the top of its stroke, and oil is drawn in from the inlet and through one of the channels, and on the down stroke is expelled into the upper of the two outlets as soon as the hole registers with it. A further movement brings the hole opposite the other groove in the pump casing, a further charge of oil is drawn in, and thus the cycle of operation is continued. The oil lead to the big end passes through the crankshaft boss, and almost touches the flywheel, on which a scroll is cut, and the end of this terminates in a hole leading to the hollow crankshaft. The stream of oil impinging on the fly-wheel is led by centrifugal force along the scroll right into the big end bearing. A hand-controlled oil pump is connected directly to the crank chamber.

Another important feature is the kick starter, which has been somewhat simplified in design. It works directly on the crankshaft, and its pinion is neatly enclosed by a cover forming part of the magneto chain case casting.

We have already referred in these pages to the ratchet brake with which the latest model P. and M. is fitted. This is now interconnected with the band brake on the rear wheel, so that this brake may be actuated either by the hand or the foot. A movement of the pedal does not alter the hand lever in the slightest degree, owing to the ingenious arrangement of the control rods. A rim brake is fitted to the front wheel.

The remainder of the machine does not show any startling features in design, and the improvements are chiefly in detail. A larger transmission shock absorber is now fitted, and the design of the spring forks has been considerably simplified. The excellent carrier now has welded joints, and on each side of it are spacious tool bags, which are securely closed by a strip steel bolt in place of the usual leather straps.

We have an interesting announcement to make concerning Messrs. Phelon and Moore, Ltd. Hitherto the firm have adhered strictly to reliability trials, since their machine, while capable of maintaining a good average, was noted rather for its excellent finish, its unimpeachable reliability, and its steady going, than for its achievements as a speed mount. However, this state of affairs is now ended, and next year the firm intend to have a sporting try at the 1920 Tourist Trophy Race, and, in consequence, we hasten to wish them the success they most thoroughly deserve.

The Motor Cycle November 20th, 1919. pp 599, 600

If you have further information or a query related to P & M please contact us