Page 92

The Sturmey-Archer Gear-boxes. There are three types of gear-boxes fitted to A.J.S. machines: the new heavyweight four-speed, the heavyweight three-speed (TBS, T9), and the lightweight three-speed boxes (T5, TB6). On the two first mentioned the layshaft is below the mainshaft, but in the latter case the layshaft is placed immediately behind the mainshaft with a totally- enclosed kickstarter drive taken through the low gear pinions. The heavyweight four-speed gear-boxes are standard S.A. gearboxes, except that they have a special end cover, having a swiveling fulcrum arm and anchorage. The clutch-operating- control on all boxes comprises a lever mechanism. Both three- speed boxes work the same, though some constructional features are different (page 97).

The Heavyweight Four-speed Gear-box (Standard on Models T6, T9, 33/2). Referring to Fig. 42, the clutch body (14a) is keyed and held by a nut to the end of the mainshaft (1). Rigidly fixed to the clutch body and moving with it are four driven plates (14) kept in contact by the clutch springs (15) with three friction insert plates (13), of which the rearmost constitutes the clutch sprocket (3) driven by chain from the engine sprocket. These friction plates, owing to their construction (see page 137), rotate when the engine is running as a single unit, and the driven plates also rotate with them, except when the clutch spring pressure is released by the lever (17) through the plunger (16). It will thus be seen that with the clutch engaged, the engine always drives the gear-box mainshaft at a speed equal to the ratio of the engine sprocket diameter to the clutch sprocket diameter (i.e. at about half engine speed).

Page 93

The mainshaft itself is carried in two bearings, that on the clutch side, where the secondary transmission thrust is received, being a heavy single-row, self-alining ball bearing, and that on the opposite side a light double-row ball bearing. The main- shaft, however, is not carried direct on the large bearing, for the gear-box sprocket (4), which is connected to the rear wheel sprocket by chain, is rigidly attached to a sleeve (5A), which also carries the top gear dog wheel (5), and the whole is free to revolve on the mainshaft with a phosphor-bronze bush as a bearing. It is the sleeve itself which is carried by the thrust ball bearing, and, consequently, the loading of both primary and secondary transmission is taken through this bearing. The top gear dog wheel is in permanent engagement with a small fixed layshaft driving pinion (9), and so the gear-box sprocket rotates whenever the layshaft is in motion, and vice versa. Adjacent to this small lay-shaft pinion is another slightly larger pinion (10), free to rotate on the layshaft and dogged on its inner side. This pinion provides third gear. At the end of the mainshaft opposite the clutch are two small pinions, the second gear dog wheel (7), free to revolve on the mainshaft, and the low gear pinion (8), which is not dogged, but is fixed to the mainshaft and in constant mesh with the large layshaft driven kickstarter dog wheel (12), which can revolve freely on the layshaft. As may be seen from Fig. 42, with the gears in neutral, the kickstarter axle, when rotated anti-clockwise, drives by means of the pawl and ratchet the large layshaft k.s. pinion (12), which, in turn, rotates the first gear pinion and thus drives the mainshaft and clutch sprocket clockwise.

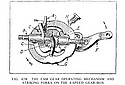

This illustration should be studied in conjunction with Fig. 42

Taking the engine sprocket into consideration, a total gear reduction of about 4 : 1 occurs. Between the top gear and the second gear mainshaft dog wheels on a splined portion of the mainshaft is one of the two sliding pinions (6). Below this on a splined portion of the layshaft is the second sliding pinion (11). Both these sliding pinions are dogged on each side, and together are capable of engaging four dog wheels.

A very clever cam operating mechanism, whose design is made clear by Fig. 42B, co-ordinates and controls the horizontal motion of the two sliding pinions, which have grooves into which the striker forks A fit. The cylindrical bases of the striker forks can slide endwise on a. fixed shaft B mounted parallel to the main- shaft, and the necessary and somewhat complex movement of the two strikers is obtained by partial rotation of a. cam plate G, into whoso curiously shaped grooves C fit closely two small studs on the striker fork bases. The cam plate itself has a central stub spindle bearing, and is caused to rotate by the gear-box lever F through the agency of a toothed quadrant E engaging a pinion fixed to the back of the cam plate. To prevent the possibility of the gears being missed, the periphery of the cam plate has five notches G, which are engaged by the end of a spring-loaded plunger H.

A - Striking forks E - Actuating quadrant (shown dotted)

B - Fork shaft (fixed)

C - Cam grooves

D - Cam plate and pinion bearing

F - Gear-box lever

G - Cam plate index notches

H - Spring-loaded plunger

Briefly, the action of the gear-box is as follows:

Fourth Gear. The upper sliding pinion is moved to the extreme left (Fig. 42) until the dogs of the mainshaft sliding pinion engage with those of the top gear dog wheel, when the mainshaft and top gear dog wheel sleeve become locked together and rotate as one. There is thus no gear reduction (pinion 11 in neutral), and the layshaft simply idles, while the clutch and gear-box sprockets rotate together at the same speed.

Third Gear. The mainshaft sliding pinion is moved to the right into the position shown at Fig. 42, while the layshaft sliding pinion is interlocked with the third gear layshaft dog wheel which is in mesh with the mainshaft sliding pinion. Here the drive is taken from the clutch sprocket, transmitted through these two pinions, the lower of which is now locked to the layshaft, and then back to the sliding sleeve and gear-box sprocket through the layshaft driving pinion and top gear dog wheel, which are in constant mesh. Only a small gear reduction, equal to the resultant ratio of the diameter of the four pinions, occurs.

Second Gear. The upper sliding piston is moved across further to the right until the dogs on the mainshaft sliding pinion interlock with those of the second gear mainshaft pinion, thus locking the latter to the mainshaft. The drive is here taken from the clutch sprocket, transmitted along the mainshaft, and passed to the layshaft through the second gear and layshaft sliding pinions to the layshaft, and then back to the gear-box sprocket sleeve through the layshaft driven pinion and top gear dog wheel. Two separate gear reductions of considerable magnitude occur.

Neutral. Neutral is obtained by positioning the sliding pinions as shown in Fig. 42, when, as may be seen, the pinions on either side of them run idly and no motion is imparted to the layshaft whatsoever. One of the sliding pinions is always in neutral.

First Gear. The layshaft sliding pinion is moved across to the extreme right until it interlocks with the layshaft driven kick- starter dog wheel. Here again two considerable gear reductions occur, the drive being transmitted to the gear-box sprocket in the usual manner after transmission via the low gear pinion and kickstarter dog wheel.

The Sturmey-Archer Three-speed Gear-boxes (Fitted to Models T5, TB6, TB8, T9). Referring to the sectional view at Fig. 43, the clutch body (51) is keyed to the tapered end of the main- shaft, and the clutch sprocket, which becomes locked to the body by the spring (12), pressing the driven plates (19) against the friction inserts of the clutch sprocket. Thus so long as the engine is running and the clutch lever (23) is not causing the mainshaft thrust plunger (10) to release the spring pressure, the mainshaft (20) rotates on. its ball bearings. On the clutch lever side a doublerow ball bearing is used, while on the sprocket side a heavy singlerow thrust ball bearing is used. Interposed between this and the mainshaft is a sleeve (26), to which are fixed the top gear dog wheel (10) and the gear-box sprocket (17). This sleeve is free to rotate on the mainshaft. The top gear dog wheel is in constant mesh with the layshaft driving pinion (29) keyed to the layshaft, so that whenever the layshaft is in. motion (top gear excepted), the sleeve and gear-box sprocket transmitting the drive also rotate at a speed equal to layshaft speed x ratio of the diameters of the two meshing pinions. Keyed to the end. of the mainshaft opposite the clutch is the bottom gear pinion (22), and free to rotate upon the layshaft and in constant mesh with it is the layshaft driven dog wheel (31), which has a ratchet on its outer face, with which the kickstarter pawl engages, thus rotating the clutch sprocket direct rid the fixed low gear pinion and this dog wheel. The mainshaft is splined for a considerable portion of its length, the unsplined part being that adjacent to the low gear pinion. Similarly, the layshaft is splined, except adjacent to the driving pinion.

Both the B.W. and the L.S. heavyweight gear-boxes fitted to A.J.S. machines work in exactly the same manner, but some constructional details, such as the striker mechanism, are different. They can be readily dismantled by removing the end plate, when the low, middle gear pinions and the layshaft may be withdrawn. Clutch shown incorrect (see Figs. 58, 60)

24 - Layshaft

25 - Drain plug

26 - Top gear dog wheel sleeve

29 - Layshaft driving pinion

30 - Layshaft sliding dog wheel

31 - Layshaft driven kickstarter wheel

37 - Kickstarter crank 51 - Clutch body 75 - Striking plate dog

10 - Clutch operating plunger 12 - Clutch spring

16 - Top gear dog wheel

17 - Gear-box sprocket

18 - Clutch sprocket

19 - Clutch driven plates

20 - Mainshaft

21 - Mainshaft sliding dog wheel

22 - Bottom gear pinion

23 - Clutch operating lever

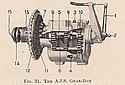

The A.J.S. gear-box has one sliding pinion only, the sliding dogwheel 9. All layshaft pinions are fixed, but the low gear dogwheel 8 is on a sleeve to which is fixed the gear-box sprocket 7. Bottom gear is obtained by coupling 9. 10. Middle gear is obtained as illustrated, and top by coupling 8, 9 together; 2 shows adjuster; 3, filler cap; 4. oil level indicator; 15, clutch spring adjusting nut; 13, k.s. ratchet wheel

Two sliding dog wheels, one on the mainshaft and one on the layshaft are simultaneously moved by a single striking- plate (75. Fig. 43) and two forks, whose endwise movement is controlled by a lever arm engaging a. ball end; positive indexing of the gear positions is provided by a. spring-loaded plunger engaging four small circular recesses in one of the fork sides. The two sliding dog wheels are responsible for connecting the primary and secondary drives, and providing the three speeds which are obtained as follows.

Top Gear (Third). The mainshaft and layshaft sliding dog-wheels are moved to the extreme left (Fig. 43), until the main-shaft sliding dog wheel interlocks with the top gear dog wheel. The layshaft sliding dog wheel thus automatically becomes free to idle on the layshaft non-splined portion, while the top gear dog wheel, gear-box sprocket, and clutch sprocket rotate as a single unit giving a direct or top gear drive.

Middle Gear (Second). The sliding dog wheels are moved slightly to the left of the halfway position, thus allowing the lay-shaft splines to engage with the corresponding keyways on the lower sliding dog wheel. The drive is then transmitted from the mainshaft via the two sliding dogwheels, layshaft, and layshaft-driving pinion back to the top gear dog wheel sleeve and gear-box sprocket. The resultant gear ratio obtained (about 1-5 to 1) depends upon the relative diameters of the two pairs of gear wheels involved.

Neutral. The sliding dog wheels are moved a trifle farther to the right until the mainshaft sliding dog wheel leaves the main-shaft splines and simply idles on the mainshaft, causing no rotation whatever of the layshaft. Fig. 43 shows neutral position.

Bottom Gear (First). The sliding dog wheels are moved to the extreme right until the layshaft sliding dog wheel engages with the dogs of the layshaft-driven kickstarter pinion. The mainshaft sliding dog wheel has now left the mainshaft splines, and idles while the mainshaft drive is transmitted to the layshaft by the bottom gear pinion and layshaft-driven kickstarter dog wheel, and thence to the gear-box sprocket and secondary transmission via the layshaft driving pinion and top gear dog wheel. Two separate gear reductions occur, giving bottom gear.