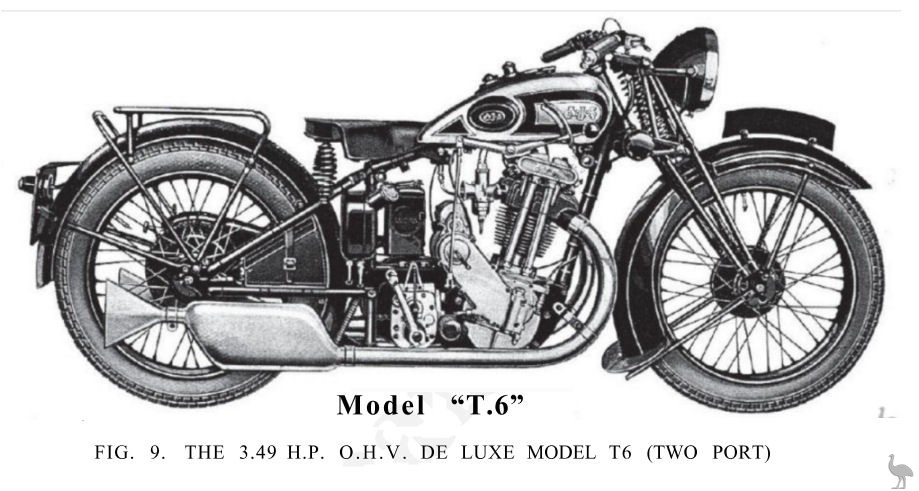

This machine, which is one of the fastest "three-fifties" on the road, combines the acceleration of a sports machine with the smooth running and flexibility of a touring machine. It can be ridden 'hands-off' below 20 m.p.h., is rock steady, and has a beautiful 'spongy' action of the brakes. At £50 it is indeed cheap, having regard to its fine finish and complete equipment. Its specification is as follows -

Page 8

ENGINE. The power unit is of 74 x 81 m.m. bore and stroke giving a capacity of 349 c.c. Two large diameter, alloy steel, tulip valves, hollowed out for lightness, are symmetrically placed at 82½° to each other in the detachable cylinder head so that, when seated, their heads are roughly flush with the walls of the hemispherical combustion chamber; slightly in front, on the left- hand side of the cylinder, is a sparking plug with its electrode points pocketed within the chamber. This arrangement is ideal, having regard to instantaneous combustion, good cylinder charging and exhaustion, and last, but by no means least, good turbulence. On ail O.H.V, engines the exhaust valve guide is a steel housing with phosphor bronze lining. The inlet guide is of cast iron (except TB6). Lubrication of guides is not provided.

The valves are operated by polished duralumin rockers, splined to the tubular rocker shafts, carried by a sturdily built rocker box, which is fixed by four pins to the cylinder head. This rocker box has an inspection cover in the centre of which is a Tecalemit nipple for greasing the push-rod ball joints. Two coil springs fitted inside the rocker spindles keep the rocker balls in contact with the rods and also prevent rocker end play. The arms carry at their extremities grub screws and lock-nuts, which enable valve adjustment to be effected at the rocker arms. The whole of the overhead valve mechanism and the two duralumin push rods are totally enclosed and adequately lubricated. With a hot engine the clearance between inlet valve and rocker is 006 in,, and the exhaust clearance is -008 in. The rockers have large area plain bearings. The crankcase valve actuating mechanism is, of course, the same as on the S.V. engines. The valve springs are noteworthy, being of the two-in-one variety. The valve movement slightly overlaps the piston stroke, and in consequence two small segments are milled off the piston crown to prevent fouling of the valves.

The piston is of aluminium alloy, and has four narrow width rings, the bottom ring being primarily designed to prevent piston slap. The gudgeon pin is hollow, and is secured in position by two spring circlips. This piston, unlike many of its type, does not suffer from that distressing malady, 'piston slap.' The correct gap at the rings is -005 in. to 010 in. The compression ratio is 6 to 1 with the standard piston, but a special high compression piston giving a ratio of 7-5 to 1 is obtainable.

Within the cast aluminium crankcase is the crankshaft assembly, comprising two heavy rimmed cast-iron flywheels of comparatively small diameter, with their main shafts running in ball bearings, and the crankpin upon which the big end roller bearing of the connecting rod is mounted. Two ball races are fitted on the driving side and one on the timing side. Those on the driving side are separated by a white-metal, oil-retaining ring (see Fig. 40). This ring has its outside grooved and drilled radially so that any oil reaching the ring is returned to the crankshaft.

The engine illustrated is a 4-98 h.p. twin-port model T8, and is shown with the Bowden carburettor. The 3-49 h.p. engines are similar as regards external appearance. T6, TB6 pistons have segmented convex crowns. All others have the fiat type chamfered at the sides. During 1933, overhead valve A.J.S. engines will be available as proprietary engines under the pseudonym 'Majestic'

Page 10

The big end bearing is interesting, owing to the somewhat unusual mounting of the rollers. The cage is of duralumin and the rollers themselves lie end-to-end in the slots and between flanges on the crank pin; the sides of the rollers are clear of the flywheel bosses, and thus there is no deleterious end thrust.

A disc-type crank case breather is not used on A.J.S. machines, but merely a release pipe from the timing chest, a plain union being screwed into the timing chest and the release pipe taken from this. A non-return valve is not included, neither is it necessary.

The timing gear is extraordinarily simple, and does its duty in a noiseless and trouble-free manner. It consists of the engine main shaft small pinion and two large half-time cam wheels. The cams act directly on the tappets, no toggles being interposed, as the tappets have half-moon feet.

The new type silencers and fishtails are very effective in reducing the exhaust noise, and should absolutely guarantee the rider against police prosecution for noise, which has recently become so prevalent. The principle employed consists of the use of blind ended, and drilled, extensions to the two pipes; and it is thus utterly impossible for the gases to flow straight through. This system was thoroughly tried out before being standardized for use on the 1932 range of A.J.S. engines, and it was found that the resultant back pressure was negligible. Both silencers and exhaust pipes are heavily plated. A flange fixing now replaces a clip or screw fastening on the induction pipe for the carburettor on all except the T5 and 33/2 engines.

CARBURETTOR. A No. 76/014A Amal, 2 jet, 2 lever, semiautomatic carburettor with bottom petrol feed is fitted, and the standard setting is - jet 150; needle position, 2; type of valve, 6/4. This gives fierce acceleration and perfect slow running. Twist-grip throttle control is provided. Petrol consumption at 30 m.p.h, is over 75 m.p.g. Riders who wish to fit an Amal 'acceleration pump' should note that on nearly all A.J.S. engines a conversion is simply effected. See notes on page 81.

IGNITION. The current is generated by a H.T. Lucas variable ignition type M.S.I. magneto chain driven off a sprocket splined to an extension of the inlet camshaft. The other sprocket fits on a sleeve keyed to the armature shaft, and has a Vernier adjustment for securing accurate timing. Actually, the flash across the plug electrodes is timed to occur 9/16 in. before the top of the compression stroke on full advance. The sparking plug used is the Lodge H.l. The magneto is a well-protected instrument, and has, of course, a clockwise armature rotation, viewed from the contact-breaker side. A circular cover held in place by a spring gives access to the magneto sprocket and Vernier adjustment

Page 11

Lubrication. Mechanical lubrication is employed. Oil is pressure-fed into the crankcase by a duplex pilgrim pump continually, but a portion of the oil fed to this pump is returned to the tank before entering the engine (see page 88). The flywheels splash it on to the cylinder walls, and oil is also pressure-fed into the timing case, whence it drains to the sump. The pump is driven from the crankshaft and enclosed within the timing cover.

Both upper and lower plungers are connected by a common lead. The upper plunger delivers oil to a false bearing on the timing end of the crankshaft, and thence through the crankshaft and flywheel to the big end. The lower pump returns some oil direct to the tank, where the functioning of the pump can be verified by the outflow from the return pipe placed immediately below the filler cap and visible on its removal.

Mechanical lubrication undoubtedly relieves the rider of a source of constant anxiety and annoyance; and also saves him no small amount of money in the long run on the score of economy in engine oil. Moreover, correct lubrication ensures the minimum production of carbon deposits on the piston crown and combustion chamber, and thereby gives the maximum mileage before the rather odious, but nevertheless easy, job of decarbonization becomes necessary. This mileage should approximate 2,000. In practice, however, the owner usually 'decokes' as soon as an appreciable loss of power and tendency to 'knock' become manifest.

Page 12

The makers recommend the use of only the highest quality oil for lubrication. Castrol 'X.L.' and 'C' are highly recommended for touring and Castrol 'R' for racing.

FRAME AND FORKS. These two supplementary units have been designed to give together a reasonably short wheel base (56/4 in.), and a 29 in. saddle height. Care has been taken to ensure good general stability at speed and on treacherous road surfaces. The A.J.S. forks are of the original 1930 pattern, and efficient shock absorbers are incorporated at the rear end of the lower fork links. The links are adjustable for side play. Fitted to the forks is a very neat design of mounting (see Fig. 14A), which permits of a lamp being bracketed in a very low position that greatly enhances the appearance. A centrally placed compression spring is embodied in the forks, and a steering damper included on all 3-49 h.p. and 4-98 h.p. models. This produces excellent steering without looseness, and the efficient steering damper when tightened down prevents any possibility of speed wobble occurring. The forks are provided with grease-gun lubrication. The frame is of triangular form of high tensile steel tubing. As may be seen in Fig. 12, the frame is really a semi-cradle type with torque tubes to the fork ends, which absorb all torsional stresses of the transmission. The bottom bracket and rear engine plates are in one piece, thus affording great strength and rigidity. The saddle pillar tube also extends right down to the lower cradle plates and torque tubes. A single rail only is employed for the top tube, this being of very large diameter.

Page 13

GEAR-BOX. The gear-box is an A.J.S. countershaft four-speed gear, fitted throughout with ball bearings, and is standard for two models. It is operated by a right-hand gate change lever, affixed to the tank on the right-hand side ; and it gives solo ratios of 5-8, 7, 12-6, and 17-4 to 1. Sidecar ratios: 6-41, 7-77, 13-9, 19-23.

Moving the change speed lever forward from front to rear position, the consecutive gears engaged are - first; neutral; second; third; top. On to an extension of the splined main shaft, which has a very robust thrust bearing on the driving side, are fitted two sprockets - one. small and one large - for primary and secondary drives, respectively. The larger sprocket, incidentally, is part of the clutch (see page 137), which is of the multiple plate and cork insert type with multiple springs, and has handlebar control on the left-hand side. No adjustment for clutch spring tension is provided. The kick-starter lever (seen in Fig. 23) is in a position such that ample leverage can be exerted upon it with the foot while astride the saddle. Its operating mechanism is entirely enclosed. Only a high grade oil made by a firm of repute should be used for gear-box lubrication, and the oil recommended is 'Castrolease Light' for summer and Castrol 'D' for winter.

TRANSMISSION. Both primary and secondary drive are by substantial xxx Vi in. pitch by .305 in. wide Coventry roller chain. The chain of the former is completely enclosed (Fig. 7), while that of the latter has a protecting guard on the upper half only, giving easy access to the chain for inspection and lubrication purposes. These guards are designed to protect both rider and chains.

An efficient shock absorber on the engine mainshaft allows the power to be absorbed gradually and thereby eliminates 'snatch,' which soon ruins any chain. In consequence, it is a very rare occurrence for a properly tensioned and lubricated chain to break on the road. The chain wears out completely long before this.

BRAKES, WHEELS, AND tyres. Quickly adjusted, internal expanding brakes are fitted to both front and rear wheels, which are tyred with 26 in. by 3-25 in. wired-on, heavy type 'Non- Skid' 'Firestones' with Schrader valves. The rear brake is operated by a foot pedal on the left-hand side and the front brake is controlled by a handlebar lever on the right side. Both brakes are very smooth and powerful in action. Fig. 13 shows the brake drum and shoes of the rear brake. Rear wheel quickly detachable; both wheels have taper roller bearings.

Page 14

TANKS. A handsome, black enameled, and bulbous nosed saddle petrol tank of welded steel is secured by bolts to lugs on the bottom frame tube, and has a capacity of 2 gallons of petrol. The filler cap is of the snap action bayonet type. Fastened by means of concealed plates are good quality rubber knee-grips. Where an instrument panel is not or cannot be specified, the gearbox driven speedometer is let into a recess in the tank and held in place by two pins. The tank on T6, T8, T9 is finished in chromium plating with a black panel and the usual transfer. A separate oil tank behind the down tube holds xxx 4Vi pints. TB6, TB8, T5 have black enamel finish and gold lining.

MISCELLANEOUS DETAILS. The semi- 'T.T.' adjustable handlebars have rubber grips with integral controls and in the centre a steering damper ; just below the engine plates are rubber footrests, adjustable for position. This combination gives a very comfortable and natural riding position. The saddle itself is a Lycett medium weight model, with special adjustable mounting (Fig. 2). Valanced mudguards are fitted. Over the rear mudguard is a strong detachable carrier capable of safely supporting a passenger; but it is not exactly a flapper-bracket (to use the latest newspaper description of a pillion seat) ; it is really intended for luggage. Between the rear fork stays are secured two pannier bags with a full kit of tools. A central spring-up stand is provided. The general finish, including the handlebars, is black enamel on a special anti-rust process. The usual parts are all heavily plated. All oil and petrol cocks are of the quick action, push type. Electric lighting (Lucas) is extra; see pages 2, 26.

Page 15

THE 3.49 H.P. 'BIG PORT' MODEL TB6

The specification of this machine, which is eligible for the 30s. tax, with electric lighting, provided it is licensed prior to 1st January, 1933, is the same as that of Model T6, except for the following -

ENGINE. The engine has a bore and stroke of 74 X 81 mm., but instead of there being two exhaust ports there is only one port tapering to 2 in. diameter at the outside. Through this large port the products of combustion emerge at high velocity, and there is no decrease of efficiency caused by having a single port.

In this engine a three-ring piston is fitted. Both inlet and exhaust valve glides (80') are steel housings with phosphor bronze linings. There is, of course, also only one silencer of somewhat different shape from that fitted on Model T6. No fishtail is provided, but the end of the tail pipe is 'pinched.' The carburettor is an Amal of exactly the same type and setting as that fitted to model T6. A Lucas 'Maglita' or N.S.A.l magneto is fitted. Ignition timing is 3/8 in. before T.D.C., and the compression ratio is 6 5 to 1.

GEAR-BOX. This is a Sturmey-Archer three-speed light-weight B.W. with enclosed kick-starter mechanism and two-plate clutch. Instead of the clutch having several springs arranged radially it has one large central spring only. The standard gear ratios are 5-25, 8-12, and 15-45 to 1.

Other variations in specification are the provision of 25 in. x 3 in. tyres, non-valanced racing type mudguards, (the rear of which is not hinged), a petrol tank of 1¾ gal. capacity and an oil tank of 3½ pints. No carrier is fitted (though this can be had as an extra) and no instrument panel is or can be specified, a Lucas "Maglita" lighting set being used instead of the "Mag-dyno" set on electrically equipped models. Also a rear stand is used instead of a central spring-up stand. Wheel base is 52 in.

Page 16: Model T8 & Model TB8 500cc OHV