Transmission side of the new twin B.S.A., illustrating the wide guards, neat chain cases, and general clean appearance.

One ot the side-by-side connecting-rods of the 1920 6 h.p. B.S.A., together with the crank pin, showing the twin roller races

The timing side of the B.S.A., showing the new and accessible gear box and the spring seat-pillar.

There is no unanimity among designers regarding the position of the shock absorber. Those responsible for the new B.S.A. favour the engine-shaft.

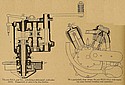

(L.) The new B.S.A. gear box, embodying s redesigned multi-plate clutch. Engagement of gears is by dog clutches. (R.) Of a particularly clean design, the new B.S.A. 6 h.p. twin engine has many features revealing road experience.

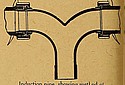

Induction pipe, showing method ol obtaining air-tight joints.

An oscillating cylinder oil pump is employed to circulate the lubricant, and is enclosed in the timing gear cover.

Spring seat-pilar on the new twin-cylinder B.S.A. It will be noticed that the springs are completely enclosed in the saddle tube of the frame.

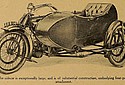

The sidecar is exceptionally large, and is of substantial construction, embodying four-point attachment.

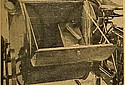

A capacious rear locker is a feature of the new B.S.A. sidecar.

The adjustable tappets are so designed that they exclude grit and are particularly simple to manipulate.

THE products of the Birmingham Small Arms Co. have always been well known for their strength and sound manufacture, so that it is not surprising to find these characteristics displayed in a marked degree in their new twin-cylinder motor cycle.

Hitherto the firm have confined their efforts to single-cylinders, which have gained a world-wide reputation, and their successes culminated in the capturing of the A.C.U. Six Days Trial team prize. The twin-cylinder is, therefore, a departure from all previous models, though, as various features have been tried out for a period of nearly three years, it cannot be looked upon as an experimental or untested machine.

A cursory examination gives one the idea that the design was carried out by experienced riders, and this impression was distinctly strengthened by close inspection of detail work.

Engine Details.

Externally the engine displays no very novel features, except that it is more than usually clean in appearance, being devoid of excrescences and dust-retaining crannies. The cylinders, which are set at 50°, are distinctly reminiscent of B.S.A. single-cylinder engines. Integral heads and cylinder barrels are used, and the radiating fins are of sensible proportions. This point deserves special mention, as of late years there has been an entirely mistaken tendency towards very thin ribs, with roots too light in section to carry away the heat from the walls. All valves are interchangeable, and the ports are extremely well designed. Valve operation for both cylinders is by means of rockers actuated by a single inlet and exhaust cam, the intervening tappets being well worth a short description. Each tappet has lugs or ears, which engage with corresponding slots in the hardened steel guide. This prevents the spindle from revolving, and consequently eliminates the use of a third spanner for adjusting purposes. The lower or lock-nut for the tappet head has a skirt sliding over the outside of the tappet guide, which effectually protects the slotted portion from dust and grit. The tappet head, which is concentric with the valve stem, is reduced in weight as much as possible.

Mechanical Lubrication.

Inside the timing case is a second two to one wheel, which serves the double purpose of forming the primary drive for the magneto and rotating a pair of worm gears, whose duty is to drive the mechanical oil pump.

This pump is of the oscillating plunger type, and has the advantage of eliminating all spring loaded valves. Oil is sucked from the tank through an adjustable sight feed lubricator, and is thus pumped to a distributer placed between the cylinders. The purpose of this distributer is to divert a certain proportion of the lubricant on its way to the crank case, and to direct it into a well surrounding the base of the front cylinder, into . which the skirt of the piston dips; in addition, the baffle plates are only present in the case of the rear cylinder, and, consequently, even lubrication is assured. A normal hand pump is fitted for emergencies.

Chain drive is employed for the magneto, or a Magdyno may be fitted if desired. The long pistons carry two narrow rings at the top and two oil igrooves at the bottom, a spring ring fixing being employed to secure the hollow gudgeon pin.

Phosphor bronze small end bearings are fitted to the H section connecting rods, the latter being slightly off-set to permit the use of side-by-side roller bearing big ends. Large diameter flywheels impart a steady turning motion to the ball bearing crankshaft, and felt retaining washers prevent the escape of oil from the main-shaft bearings.

In order to ensure accurate machining, there are no blind holes in the timing cover, the exposed spindle ends being covered by special caps. One other feature of the engine, the inlet pipe, deserves special mention. It is cast with a view to eliminating all sharp corners.

One flange is secured to the inlet port by a screwed ring and a similar fixing is utilised for the second flange, but, before this is screwed home, all chance of air leakage is avoided by the use of a special sleeve screwed into the inlet port which can be adjusted outwards to meet the flange.

New Type of Clutch.

Transmission is by 5/8 in. x 3/8 in. chain throughout, the B.S.A. cush drive being incorporated with the engine sprocket, and an internal expanding brake with the rear driven sprocket.

A seven-plate Ferodo-faced clutch transmits power to the gear box, which has been redesigned in detail. The kick-starter mechanism is now entirely enclosed, a spring tooth ensures easy engagement, and the pedal is returned by an enclosed clock spring. The gear striking mechanism is also enclosed and embodies a simple quadrant, locked by a spring plunger which positively ensures correct gear mesh at all times. Another refinement is the fitting of an oil filler hole at such a level as to prevent over-filling of the gear box. It should be added that all gears are constantly in mesh, the change of ratio being effected by dog clutches.

One of the neatest features of the machine is the system employed for obtaining detachable and interchangeable wheels. Taking the rear wheel as the most interesting example, the combined sprocket and brake drum is mounted on the chain adjusting mechanism, and rotates on a roller bearing entirely separate from the wheel hub. The drive is transmitted through serrations on the drum, which engage with internal serrations in the hub, a distance washer taking up the lateral motion necessary for detaching the wheel when the spindle is withdrawn. A small point indicative of careful design is instanced by the construction of the chain adjusters, which are of exceptional strength and spigoted into the forked lug in such a manner that it is impossible for them to drop out. All wheels are shod with 28in. x 3in. Dunlop extra heavy tyres, or Palmer light car tyres, in each case fitted to flat base rims.

Both cycle and sidecar wheels are interchangeable, and for this reason a dummy rim, to suit the inverted front brake, is fitted in each case.

Every care has been taken to render the machine weatherproof, and 8¼ in. flat guards are used both in front and rear. These guards have special valances, rolled over internally to provide channels to conduct liquid mud to the lowest point of the guard, and a special front mud shield forms an additional protection tor the engine and rider.

Cast aluminium cases, made in four parts entirely enclose both driving chains, and. in spite of the fact that they are very readily detachable, special facilities for lubrication and drainage are provided.

The two outstanding features of frame construction are the new spring forks, in which the rebound spring has given way to a considerably longer and more flexible compression spring, and a very neat and simple spring saddle pillar. This latter consists of a beam hinged at the front end to the top tank tube, and carrying the saddle at the rear. The centre of the beam is supported by a coil spring, in compression with, in addition, a rebound spring. The whole of the spring mechanism is enclosed and protected by the saddle tube, though it is easily removable for inspection or lubrication.

The tank holds over two gallons of fuel and three pints of oil. Sidecar lugs are, of course, incorporated with the frame. With regard to fittings and finish, it is only necessary to remark that these are well up to the B.S.A. standard of excellence.

Amongst the various items which give proof of careful and practical design, the large aluminium silencer rnay be mentioned. This is so arranged that the gases from the cylinders enter at one corner of a rectangular receptacle, and are led round a baffle plate, finally leaving the chamber by means of a long tail pipe attached to the same side as the entry pipes. A large inspection plate on the end opposite to the pipe bosses enables the chamber to be inspected or cleaned, but it should be emphasised that there are no narrow slots or holes to become choked by oily exhaust gases.

All the exhaust valve lifting mechanism is enclosed in the timing gear case, the cable attachment projecting from the top of the cover in such a manner as to prevent oil leakage, and the timing cover plate is spigoted for the greater part of its periphery. In fact, every possible precaution has been taken to render the engine clean and oil-tight.

A special sidecar has been constructed to suit the machine; the lines are pleasing, and the body is particularly roomy and well sprung, leaf springs being fitted in front as well as at the rear. Four points of attachment are provided.

It should be noted that, although this new model will be exhibited at Olympia, delivery will not commence before next February. A limited number of demonstration machines will, however, be in the hands of B.S.A. agents a little earlier.

The Motor Cycle October 2nd, 1919.